Tandem station for several operators

Complete Solutions to Ensure

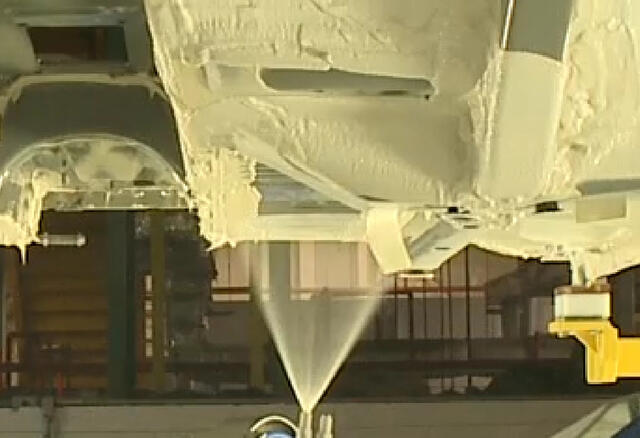

- Constant material delivering

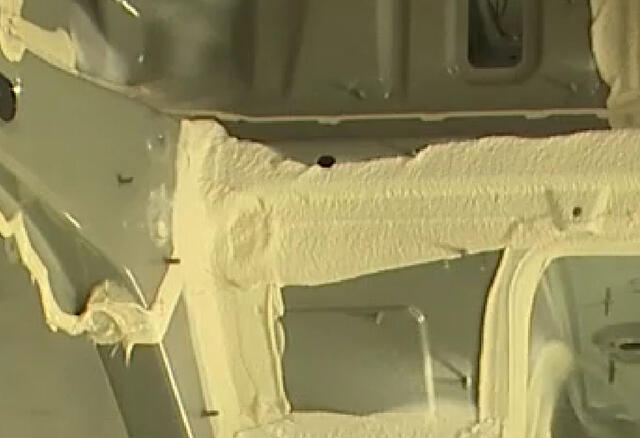

- The insurance of an homogenous bead

- High autonomy with tandem feeding

- No more production stop due to a lack of material

- Constant production capacity even on harsh condition

- Seals pump are selected according to the material to carry, in order to increase their service life

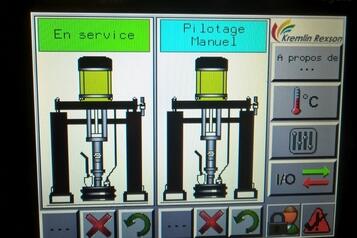

- The Rexflow controller avoid any pump run away and control the hoses temperature

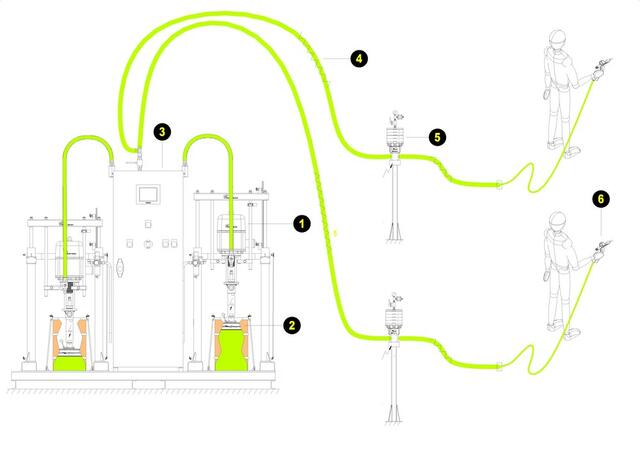

Concept Layout

Chop check piston pump

The selection of the pump size depend on the material characteristics and the number of application station to feed

Insure proper material temperature to facilitate the pump feeding

Touch screen controller managing:

- Heated zone,

- Pump start & stop,

- Pressure regulation,

- Runaway protection…

Insure constant temperature on the hoses to reduce as much as possible the pressure losses

Allows precise adjustment of the required flow to each gun

Different extrusion nozzle size available

Modular conception

This solution is modular and fits all your needs to:

- Different drum size

- Pilot the regulator from the Rexflow unit

- Deliver material to more operator