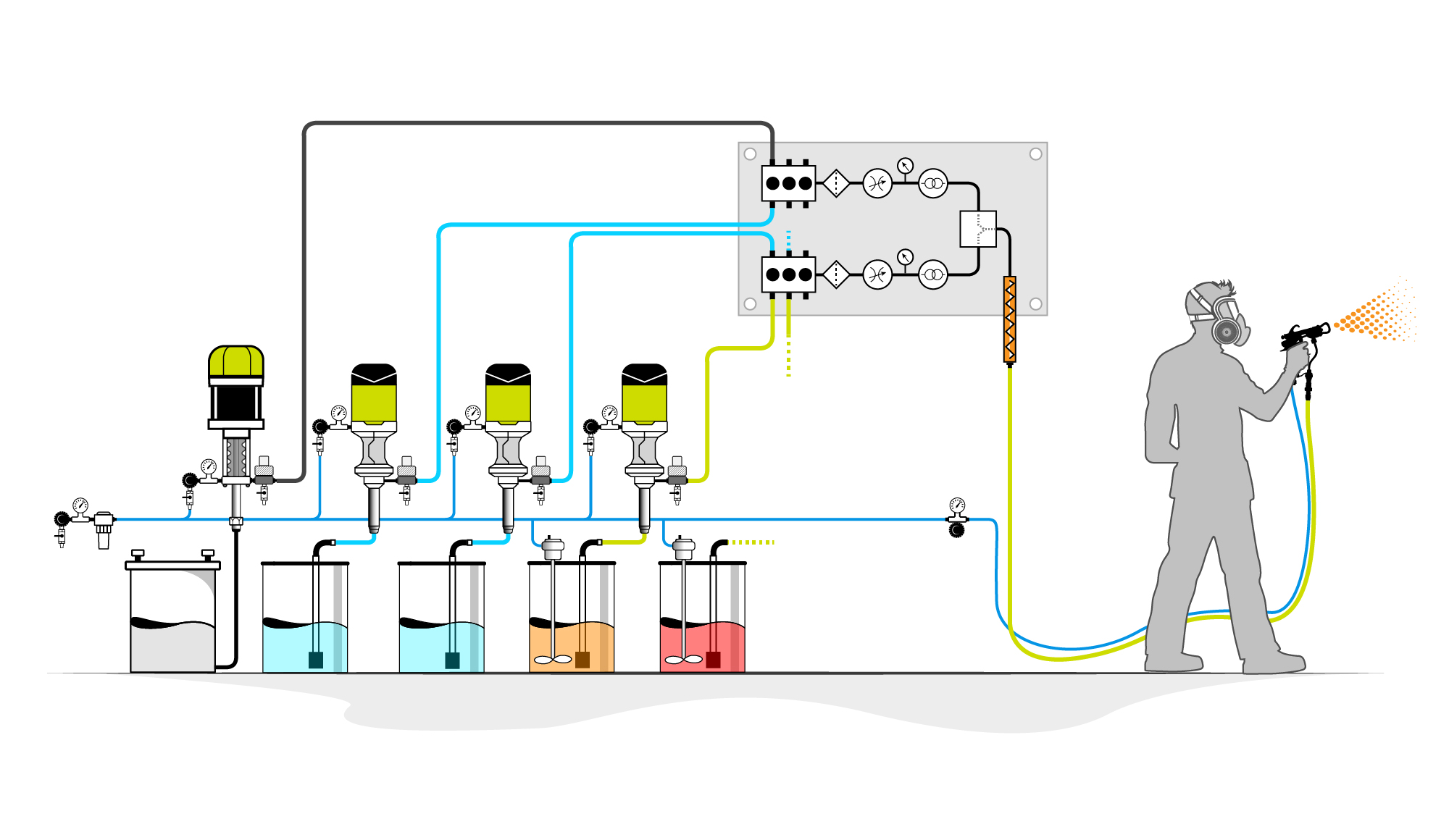

Manual application solution for solvent-based and water-based two-component paints

Save up to 30% of paint and achieve high finish quality with the Sames Kremlin Airmix® manual gun combined with 2K Cyclomix® paint mixing technology.

Efficiency: 30% quantitative savings in paint and 25% application time thanks to Cyclomix® Evo paint, solvent, and waste management and high transfer efficiency with Airmix® technology.

High quality of finishing thanks to Airmix® technology.

Productivity: Automate your coating process and boost production capacity by more than 30%.

Long pump lifespan ensured by Flowmax® technology, which prevents any contamination.

This phenomenon is the result of an irregular spray pattern with not enough or too much patina applied to the same series of parts.

To eliminate this phenomenon, we recommend Airmix® spraying.

For manual applications: Xcite®+ Light Airmix® manual gun

For automatic applications: AVX Airmix® automatic gun

This phenomenon occurs when there is too much air in the paint flow and too much product applied in a single coat to the part.

To avoid any orange peel effect, we recommend choosing Airmix® technology:

For manual applications: Xcite®+ Light Airmix® manual gun

For automatic applications: AVX Airmix® automatic gun

Wasted material, short pot life, and constant cleaning don't have to be the norm. Automatic mixing & dosing simplifies the process, reduces waste, and ensures perfect results.

See More?

The Hidden Costs of 2K Paint Application: Are You Wasting Time & Money?

Industrial sprayers working with two-component (2K) paints know the struggle: precise mixing, short pot life, excessive waste, and constant cleaning. These challenges slow production, increase costs, and impact finish quality—but they don’t have to.

Common Pain Points in 2K Paint Application

❌ Inconsistent Mixing – Incorrect ratios lead to curing issues, adhesion failures, and rework.

❌ Short Pot Life – Hardened paint wastes material and clogs equipment, leading to downtime.

❌ Solvent & Cleaning Costs – Frequent flushes waste time, increase solvent use, and create compliance risks.

❌ Manpower & Efficiency – Manual mixing and dosing require skilled labor, but mistakes still happen.

How Automated 2K Mixing & Dosing Systems Solve These Issues

✅ Precise, On-Demand Mixing – Eliminates ratio errors and reduces material waste.

✅ Longer Equipment Life – No more cured paint in hoses and guns, reducing maintenance costs.

✅ Lower Solvent Use – Automated purging minimizes waste and improves compliance.

✅ Consistent Quality – Every batch is mixed perfectly, ensuring flawless finishes.

If you’re still hand-mixing 2K paints, how much are rework, waste, and downtime costing you? Let’s talk about how an automated mixing & dosing system can transform your paint process.