High Viscosity Supply systems

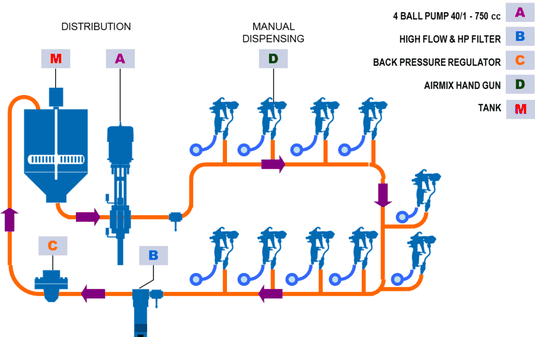

When it is needed to supply several applicators in different places with only one material supply place (distribution room).

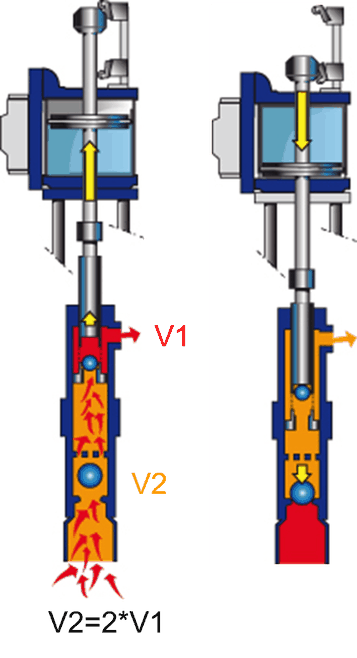

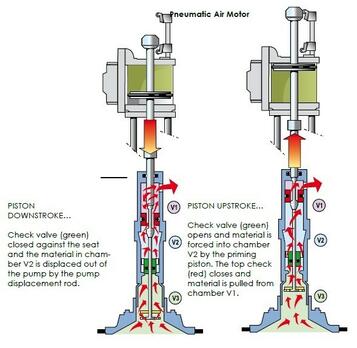

2 ball pump can deliver thick material up to 30,000 cP

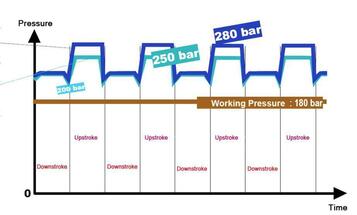

2 ball pump output pressure is unstable from up and down movements, it needs to be regulated after the pump.

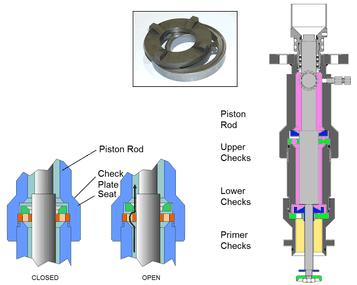

REXSON QUATRO pump HP can pump thick material when primed with another pump place on a follower plate plunged in the drum of material.

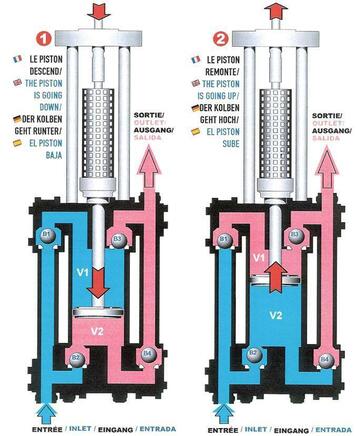

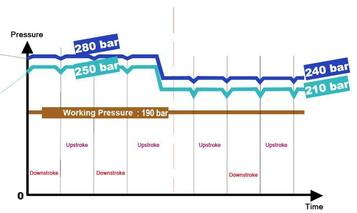

4 ball pump output pressure is more stable than 2 ball pump, it needs to be regulated afterwards, however it really improves regulation loops. It also allows recirculation of the material to get it always fresh for dispensing.

For higher viscosities ( > 30,000 cP) we use chop check pumps

For abrasive material or high temperature (hot melt), we use S1 pump which is a unique design with metallic seals.

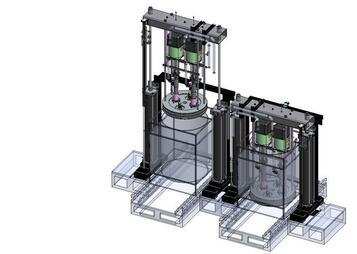

For high volumes to deliver to the system, we can fit up to 4 pumps on our follower plates.

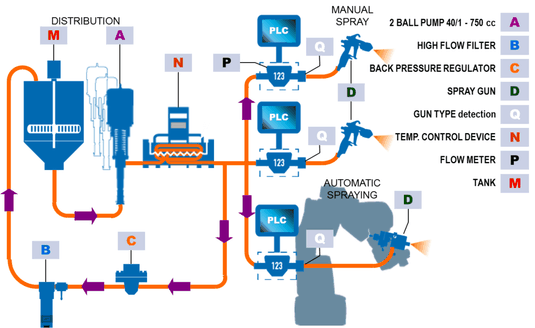

Circulating system medium viscosity

To be able to deliver material under the right flow, pressure and temperature, we design and install Supply systems with recirculation (simple loop or single pipe system).

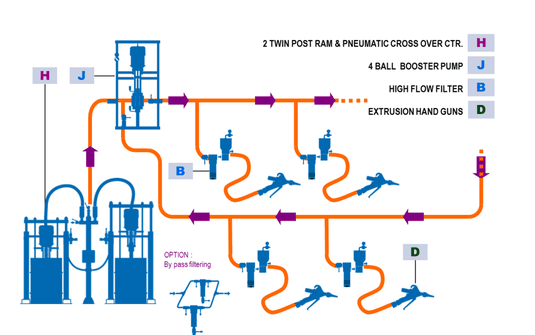

High Pressure Supply system

When viscosity increases (>30,000 cP) we need to use chop check pumps to pump from the drum, and if the piping is long (>100m) we will use booster pumps to get the right pressure and flow at the application points.

Manual, automatic or robotic applicators can be used for dispensing or spraying the material on the part.

Medium pressure controlled system

For high performance process with full control of the parameters in close loop, like material temperature and flow, we will use additionnal equipments. Local heat exchangers with insulated hoses, or heated hosed (water circulation with a jacket around the hose), mass flowmeter and close loop with controller shall be implemented.

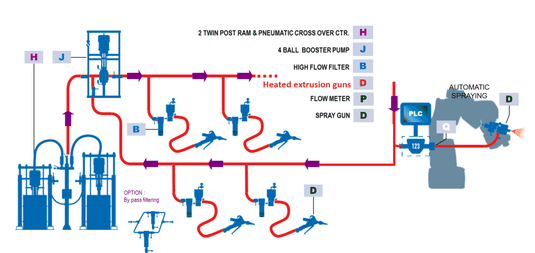

High pressure controlled supply system

For high performance process with full control of the parameters in close loop, like material temperature and flow, we will use additionnal equipments. Continuous heating from the follower plate, pump, hose to the applicator, mass flowmeter and close loop with controller shall be implemented.

We have extrusion heated guns for specific process.