2 Ball

Viscous feeding technology

Our 2 ball pumps are equipped with a pneumatic motor (for power) and a ball hydraulic (driven part). The majority of our pumps are double acting pumps. Any sealant or adhesives that is pourrable can be pumped by a 2 ball system.

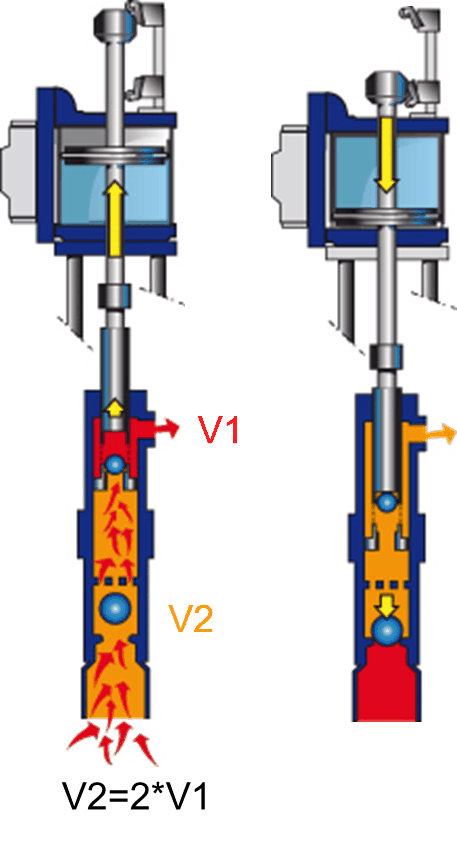

Operating principle

- When a piston down strokes, a suction valve (big ball) is closed against the seat and the material in the chamber (V2) is displaced out of the pump by the pump displacement rod.

- When the piston up-strokes, a suction valve opens and material is sucked into chamber (V2). The exhaust valve (small ball) closes and material is pulled from chamber (V1).

The piston moves on the upper part through a lubricating cup to avoid overheating by ensuring continuous lubrication.

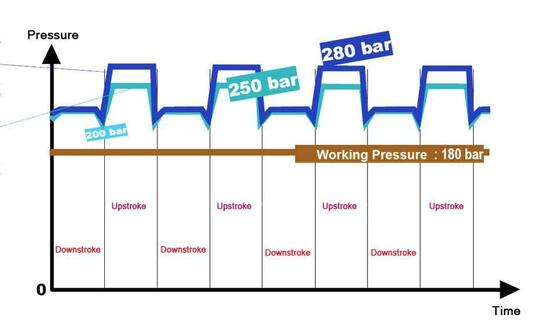

Pressure at the output of the pump

Depending on the inversions, the pressure will change between 2 values high and low.

To get a smooth flow at the end of the supply line, it is recommended to use a regulator adjusted below the lowest output pressure, then we can get a stable pressure at the working flow.

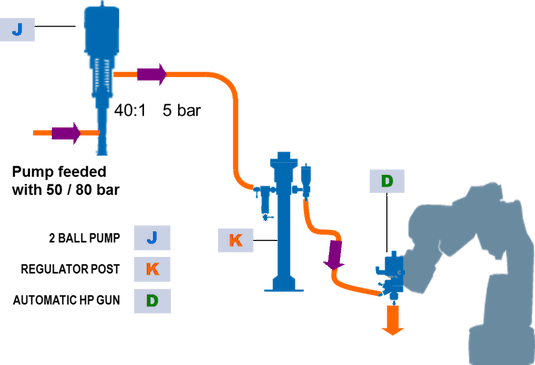

Typical installation

The pump is supplied with material under pressure, or it can be directly mounted on a RAM unit with following plate.

After the pump we use a High Pressure filter and then a pressure regulator before the dispensing gun.

because the suction foot valve has a large passage.

- Stainless steel construction

- We can adapt the ball material and packing

with balanced fluid delivery on up and down strokes.