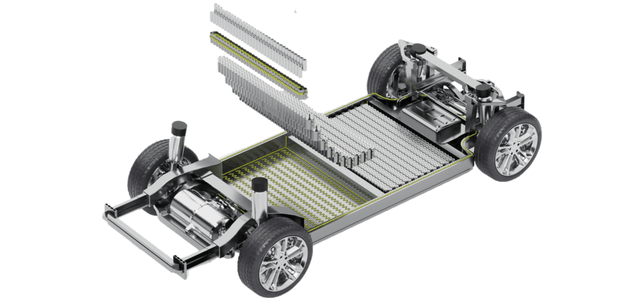

1K大流量涂胶解决方案

1K大流量涂胶应用系统是一种功能强大、高效的解决方案,旨在保护电池模组免受水分、灰尘、腐蚀、噪音和磨损的侵蚀。这种先进的定量和应用系统与所有类型的PVC密封剂兼容,确保均匀地施加坚固的保护层。L1K定量机的大流量使其成为实现大规模生产的理想选择,提供可靠的密封,延长电池模组在各种环境条件下的寿命和性能。通过提供精确和一致的密封剂涂胶应用,该系统确保了关键部件的最佳保护和耐用性。

Which equipment do we offer?

Sames Intec pump stations are known for their proven and durable design. The system for conveying high viscosity materials can operate cold or fully heated, with a single or a double barrel system (20/30/50/200 liter). A large choice of seal packings, pump powers and feeding capacity cover all sorts of applications.

Our 200L twin ram station 53C360 allows a maximum flow rate of 3,6 l/min and a maximum pressure of 320 bar.

The 1300cc electric L1K dosing unit covers all high viscosity applications in Paint shops for Liquid Applied Sound Deadener, Under or Inner Body Sealing and Coating and Liquid Applied Transfer Coatings. It is perfectly suited for high material volumes, high pressures up to 250 bar and high flow rates up to 9 l/min. With a footprint of 300x540mm, it is very versatile and compact in use. Thanks to its clever design and robust components, the L1K dosing unit offers a long service life even with abrasive materials (FiFo).

The iKS 600cc electric shotmeter for 1K materials convinces with its high application accuracy (FiFo) and easy maintenance.

The Infinitec 1K system ensures a continuous material flow thanks to an electrified quatro pump.

The OV8 gun for high flow and high viscosity applications is equipped with a carbide seat and needle and an 8mm valve. The seal cartridge is lubricated.

The 400 bar Airless automatic gun ensures an excellent finish quality due to very fine atomization at medium to high flow rates. More than 50 years of experience for sure speak for themselves.

If you would like to explore our complete range of applications in battery manufacturing, please consult our dedicated market page.