2K Low-medium volume application

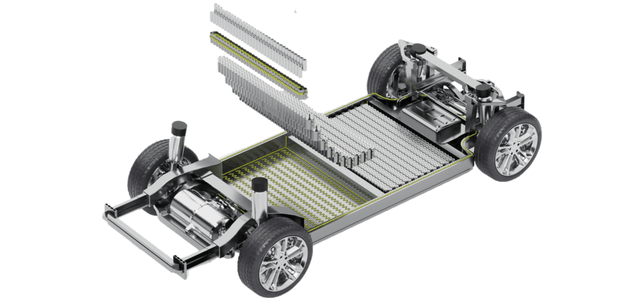

在电动汽车电池制造中,将电池与2K环氧树脂、聚氨酯或硅酮等粘合剂粘合在一起对于结构完整性和热管理至关重要。2K环氧树脂和聚氨酯(PU)粘合剂因其出色的强度、耐用性和抗机械应力性而主要用于结构粘合。这些粘合剂确保电池单模组即使在严苛的车辆运行条件下也能保持牢固连接。此外,这些材料具有优异的导热性,有助于电池运行过程中的有效散热。硅酮粘合剂以其灵活性和耐高温性而闻名,通过在热膨胀和收缩的情况下保持粘附性来补充这一点,从而提高了电动汽车电池模组的整体热管理性能和安全性。

Which equipment do we offer?

Our iKS tandem dosing units assure best in class precision and accurate dispense for high viscosity applications. The iKS1 electric shotmeter covers capacities ranging from 15 to 400cc and work with a FIFO principle. Each shotmeter dispenses 2 components to a static mixer.

Sames Intec pump stations are known for their proven and durable design. The system for conveying high viscosity materials can operate cold or fully heated, with a single or a double barrel system. A large choice of seal packings, pump powers and feeding capacity cover all sorts of applications.

For large productions, 200L or 1000 L dual ram units are fitted best.

A cutting-edge vision system ensures precise bead positioning, dimension, and continuity in real time. It seamlessly integrates into gluing equipment, offering automatic bead finding within designated contour areas.

In cooperation with the leading manufacturers of inspection equipment for adhesive beads, we offer seam inspection systems in 2D and 3D as an option. They are useful for checking the material application of 1K and 2K dosing units.

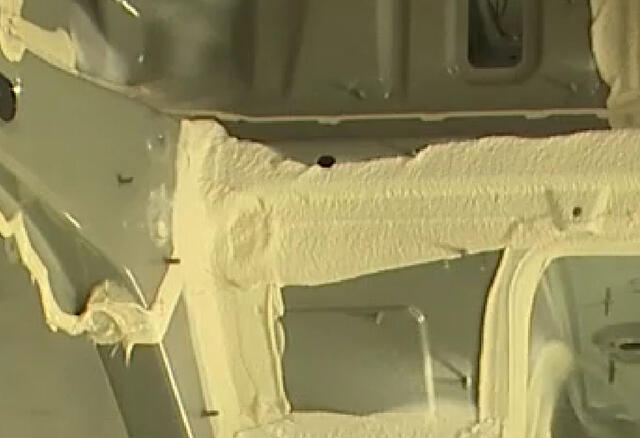

For some applications in body in white, pre-treatment of the surfaces before the bonding process is recommended to ensure a clean and adhesive substrate. This is the case if the component has residues of grease, oil or dust. If this is not done, the manufacturer risks reducing adhesion and the full effectiveness of the bond.

The proven ATMR system from the Sames Intec range was specially developed for the pre-treatment of surfaces in car body construction. The system is based on felt cubes that are soaked with cleaning agent and then run along the intended adhesive track of the component.

If you would like to explore our complete range of applications in battery manufacturing, please consult our dedicated market page.