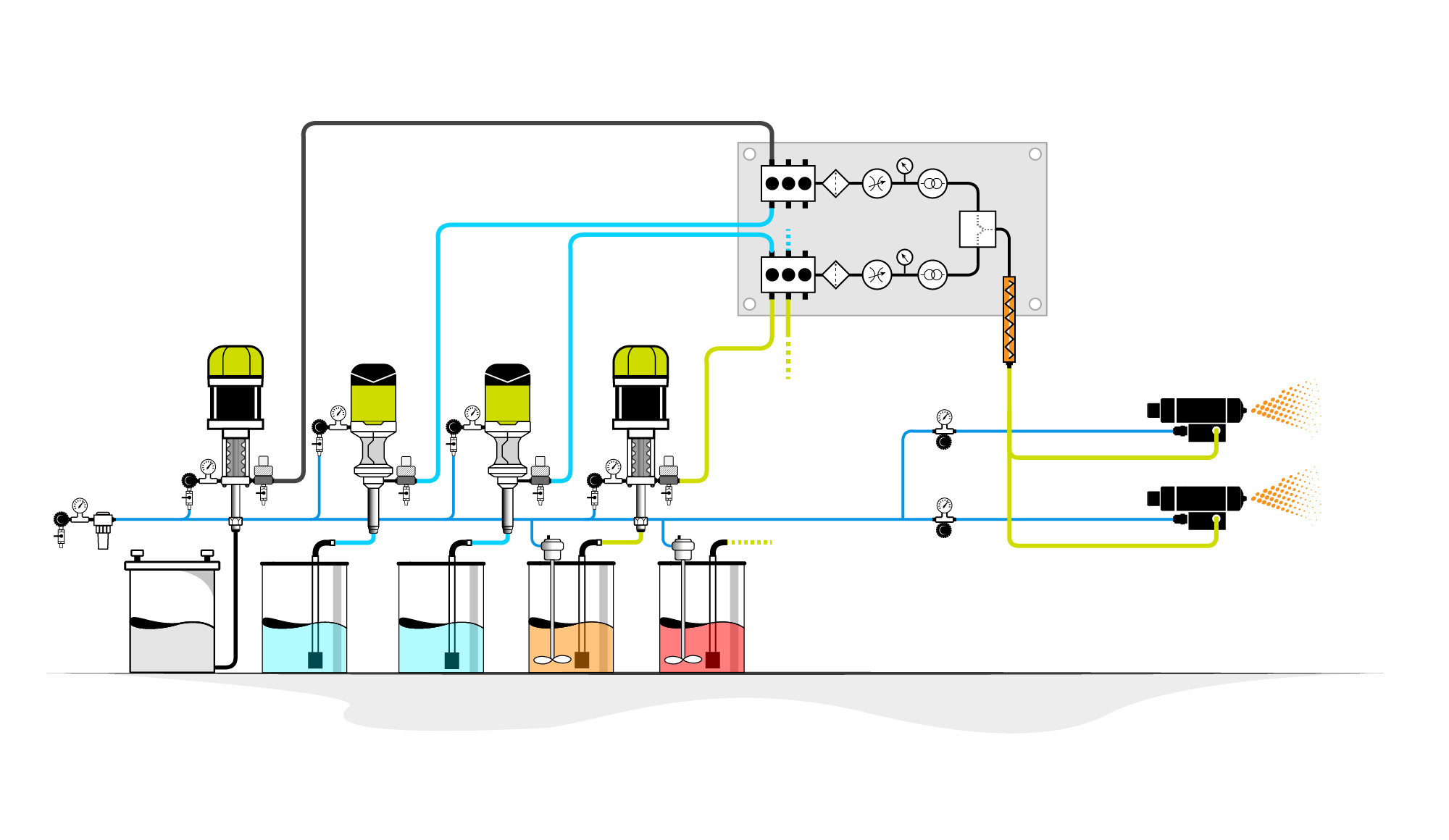

Automatic application solution for solvent-based and water-based paints on flatline machines

Increase your productivity by 20% with automatic Airmix® application technology for 1K or 2K paints, and reduce your paint consumption by 30% thanks to Airmix® and Cyclomix® Evo.

Performance: High reliability of dosing, very high-quality finish, installation compatible with UV products, acid-catalyzed paints, solvent-based and water-based paints, polyester, varnishes, and high-gloss coatings.

Productivity: Installation controlled from the flatline machine, in controlled mode, or manually. Monitoring and automatic adjustment of mixing ratios.

Durability: Flowmax® pumps designed for long service life, featuring specialized compatibility with polyurethane hardeners (isocyanates). Paint remains ready-to-use with stable viscosity ensured by continuous recirculation.

Versatility: This modular solution is designed to support a broad range of paint applications. It allows you to add extra spray guns, such as those mounted on rotary machines, adapts easily for 3-component paint systems, and minimizes mixed-product hose length by positioning the mixer as close as possible to the application point.

Airmix® combines the quality of finishing close to the Airspray with the performance and productivity of Airless. This results in a more homogeneous application, less overspray, and better productivity.

Thanks to its transfer efficiency (often over 80%), the Airmix® technology reduces paint consumption by 15-30% compared to traditional systems.

Less paint used = less costs + less waste

Airmix® spraying generates a fine, even atomization with better film coating.

The result: Consistent, high-quality finishes with fewer rework or visible defects (dust, drips, overloads).

Yes, Airmix® automatic guns are designed for stable and repeatable application on flatlines, including high speeds.

This ensures consistent performance throughout the day, eliminating the variability associated with manual operations.

Increased first-time compliant parts rate.

- Reduced downtime for cleaning and rework

- Ability to run longer with high-efficiency nozzles and easy-to-maintain systems

No. Airmix® automatic guns are designed to be reliable, durable, and easy to maintain.

- Tips and needles have a long service life, especially with water-based paints

- Disassembly is quick, limiting machine downtime

Direct savings on paint and solvent consumption.

- Productivity gains and reduced non-conformities

- Improved perceived quality, resulting in fewer customer complaints

- Generally, the ROI is between 6 and 12 months depending on the volume of production

Less overspray = less polluted air in the cabin.

- Reduction of VOCs thanks to the reduction in solvent consumption

- Less paint and solvent waste during cleanings

Airmix® is specially adapted to water-based paints, guaranteeing a stable spray and even application.

With the right pumps and regulators, you can also work on more viscous products without losing quality.