Cleaning system

Let’s talk about your projectPatented solution specially developed for surface pretreatment to ensure optimal adhesion of the adhesive material to the substrate.

The patented ATMR cleaning system is used for both cleaning component surfaces and applying functional fluids before the application of adhesives and sealants. If grease, oil, or dust residues are present on the component, this can impair the adhesion of the material.

Discover our solution

Unlike conventional cleaning methods with spray technology applied to the component, the advantage of our cleaning system lies in the precise dosing of the cleaning agent into a felt cube.

The intelligent control technology can individually adjust the saturation level of the felt in each component section. This reduces emissions, saves cleaning materials, and limits the functional fluid to the adhesive bead path. For optimal cleaning results, the contact pressure of the applicator on the substrate can be adjusted as needed. The intuitive operation of the system ensures smooth, fully automated production.

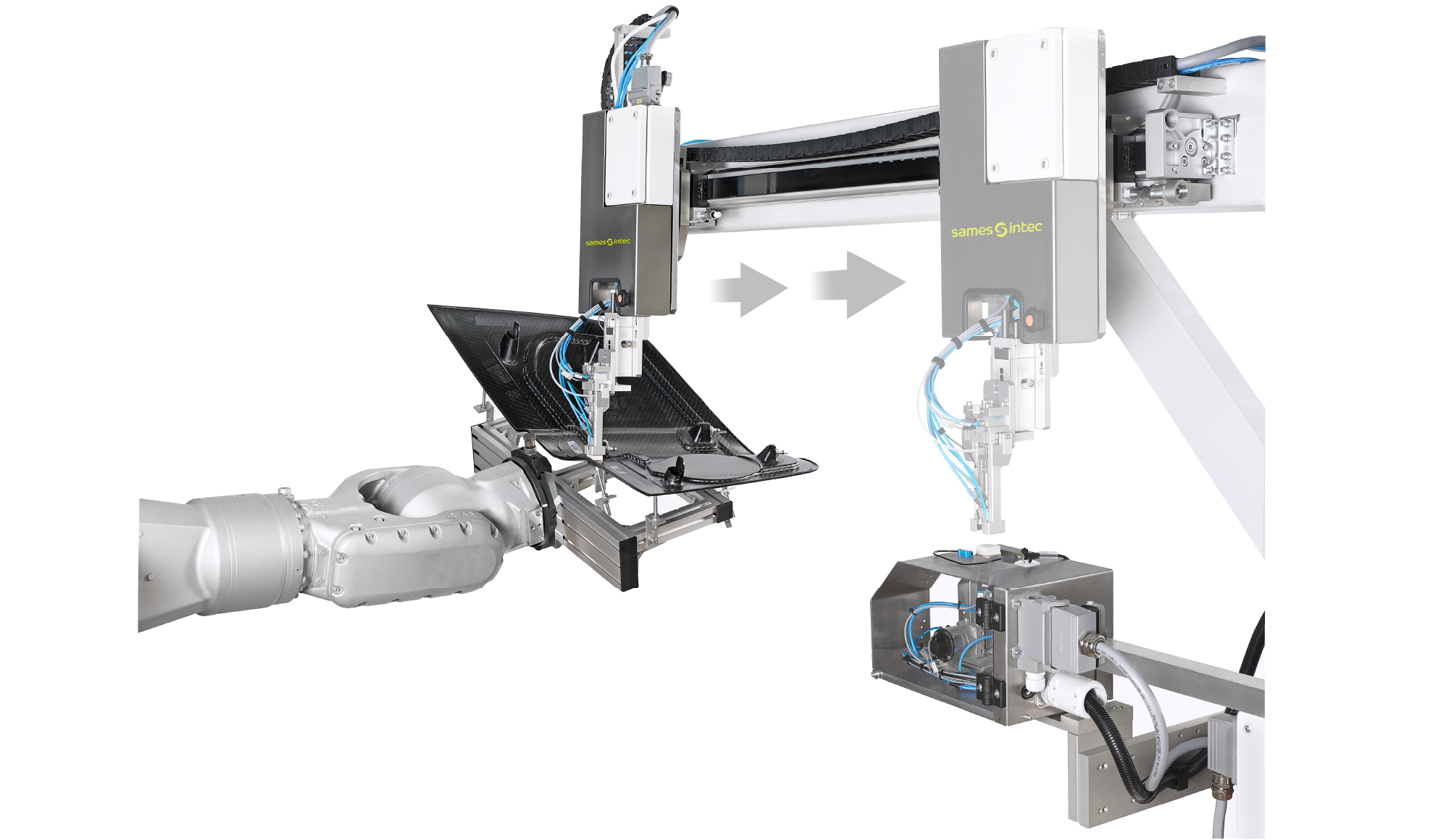

Additionally, the smart design with a modular structure allows for easy integration into your system. Our cleaning system is available in various configurations. For example, you can choose to mount the application head on either a robot or a stand. The felt pieces come in two different geometries (16 mm and 25 mm width). We are happy to advise you on your specific application!

Interactive diagram for information purposes

Main benefits

Precise dosing of the cleaning agent

Smooth, fully automated production

Individually adjusted saturation level of the felt to save material, emission and optimal cleaning.

Cleaning system solution FAQ

Let's get in touch-

Why is cleaning necessary before applying adhesive?

Grease, oil, or dust residues on the component can reduce adhesive performance. Cleaning is essential to ensuring proper adhesion of the material.The choice of cleaning material depends on the type of contamination. The felt system guarantees process efficiency: Unlike brush or spray systems, it precisely controls the amount of cleaning agent and uses robot-guided paths for accurate positioning. -

Is this system fully automatic?

Yes, the conveyor system delivers felt pieces one by one to the application head, which ensures precise application of functional fluids on predefined substrate surfaces. Pneumatic height adjustment and variable contact pressure compensate for component irregularities, while the fluid amount can be accurately regulated and adjusted as needed.After use, felt pieces are automatically discarded into a discharge container. The only manual tasks for operators are loading new felt into the charger and removing used felts from the container.