Coating gas tanks with electrostatic rotary-bell

Save up to 50% of paint, 30% of cycle time and obtain better finishing quality with Sames' Nanocoat robotic electrostatic rotary bell spraying.

Gas cylinders are coated with liquid or powder paints, using manual or automatic application systems, to meet stringent environmental protection requirements while ensuring maximum productivity.

When coating is performed before valve assembly, powder coating is a viable option. However, when valves are already installed, or during bottle maintenance operations, liquid paint application is preferred.

These cylinders are typically color-coded, requiring fast and reliable multi-color coating systems, especially in automatic production lines.

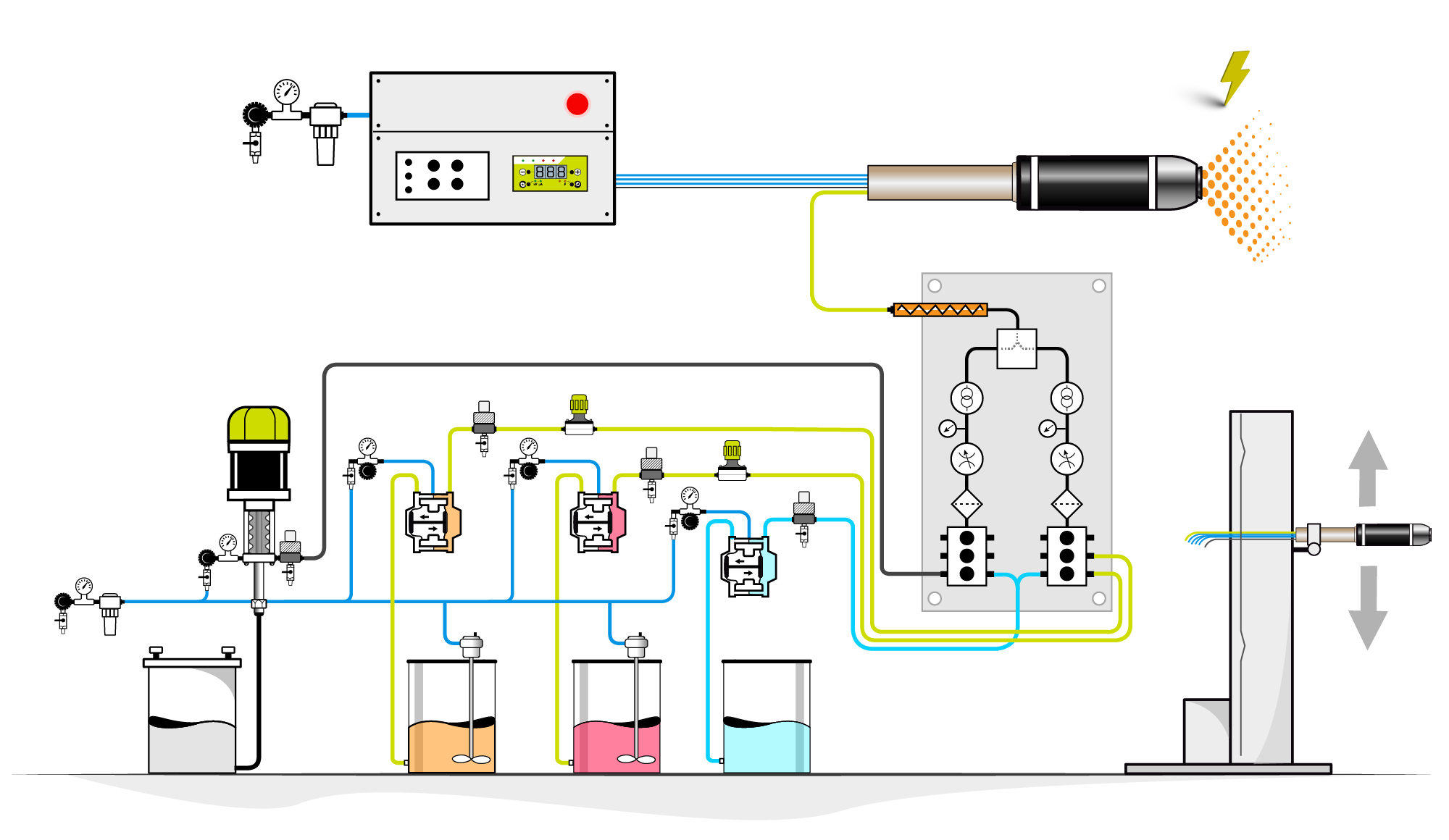

For operations demanding a high film build (80–120 µm) in a single pass, with fast color changes, high transfer efficiency, and high throughput, Sames recommends using a rotary electrostatic bell applicator with 2K paint systems.

In this configuration:

Bottles are transported via a stop-and-go conveyor, each rotating on itself for full surface coverage.

The bell sprayer is mounted on a reciprocator, enabling precise vertical motion.

Color change blocks are installed close to the bell, at the rear and midway height of the reciprocator, fed by a centralized paint kitchen, ensuring fast and clean transitions between colors.

Finally, a fixed Airspray gun applies the top color code marking in a wet-on-wet process for identification and compliance.

Up to 50% higher transfer efficiency, thanks to the superior wraparound effect of the bell compared to a spray gun.

Increase productivity by up to 30%, thanks to the highest paint flow and maximum impact surface delivered by bells compared to spray guns.

Reduce paint consumption and minimize environmental contamination.

Yes — and for a long time. This solution is already running successfully at multiple industrial sites, across various regions and major gas cylinder manufacturers. You can rely on our solid experience and proven performance. Just contact us — we’ll be glad to share references and support your project