Vertical exterior finishing & reconstruction drum lining with Airmix®

Best finishing mileage and ROI, save paint with efficient color change, thermal control, operator-friendly, and easy servicing solution.

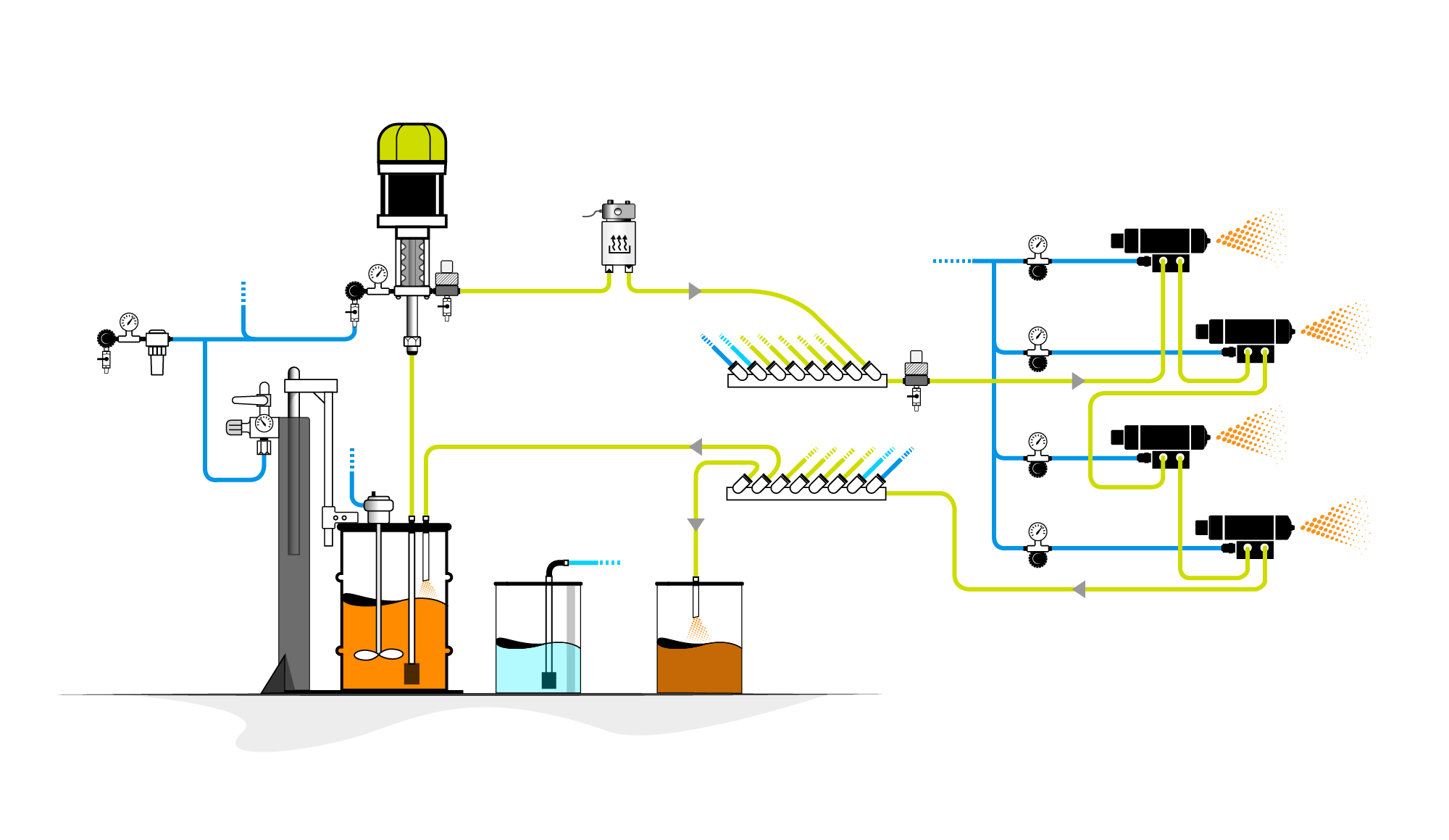

This high-pressure multi-color Airmix® solution enables automated tri-tone drum coating with fixed guns and precise color control at each station ensuring flexibility, efficiency, and clean transitions between production batches.

Paints of different colors are agitated inside their delivery drums, heated, and circulated to the different stations at high pressure. All paints are ready for use at each station, thanks to a color-change valve, upstream filter, and regulator.

In the stations, a stop-and-go conveyor brings the drums one by one in front of a collection of fixed Airmix® guns. Once in position, the drum rotates on itself and the guns spray. Guns can be fed by different colors to achieve three-tone coating—like red at the top, blue in the middle, and green at the bottom.

Finally, when it's time to change color or stop production, a dumping line collects the wasted paint and rinsing solvent.

Achieve the highest coating quality with advanced paint conditioning, precise thermal control, and Airmix® spraying technology

Efficient color change process with zero downtime and minimal paint and solvent waste

Unlimited color combination for each batch with no process limitations

Quick return on investment, thanks to the optimized paint circulation system design and the use of Airmix® spraying technology

For this type of product, you can use its geometry to your advantage by selecting an edge or bump as the dividing line between two color areas. This approach creates a sharper, more defined color separation. Airmix® and Airless technologies typically deliver clear edge definition that meets most customer requirements. For stricter specifications, a masking process may be necessary.

Yes, our drum coating solution for 55-gallon drums (international standard) is already deployed at multiple industrial sites worldwide, including for two-tone and three-tone applications. It’s a proven, reliable process.

If you have a specific need or project in mind, contact us—we’re ready to support you.