Accubell® internal charge canister system for waterborne paints

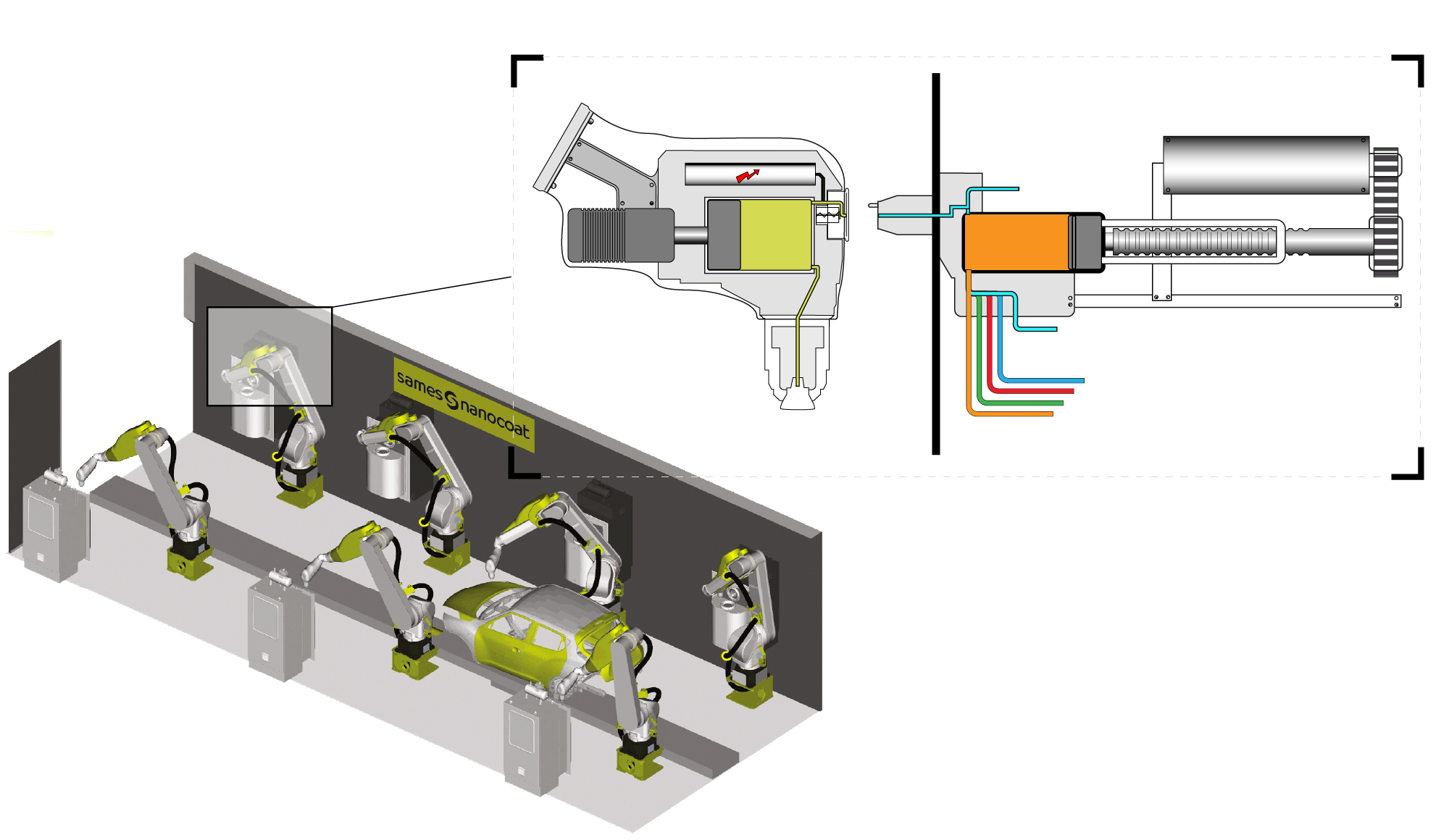

Accubell® 709 Evo is a robotic internal charge electrostatic solution dedicated to water-based paint with a docking station fixed to the booth wall.

Accubell® integrates the sprayer, color changer, automatic cleaner into one fully robotic system.

The patented Accubell® 709 Evo features a dual-canister system arranged in series. The first canister, located inside the sprayer, robotically handles the paint, while the second canister, positioned in the docking station on the booth wall, prepares paint for the next job. So, as one canister paints, the other readies the next color, enabling changeover in less than 5 seconds.

Each canister uses a servomotor for accurate paint dosing with a tolerance of only +/-1 cc. The sprayer's internal high-voltage cascade ensures maximum efficiency for both plastic and metallic parts.

Thanks to its compact design, Accubell® can handle exterior, interior, and plastic painting applications.

Highest transfer efficiency for waterborne paint

Fast color change

Low paint loss during color change

Perfect dosing accuracy

Over 1200 units installed worldwide

Accubell® 709 Evo is a compact internal charge bell atomizer with a docking station fixed to the booth wall.

• Compact atomizer for all applications

• Fast color change

• Minimal paint loss

The Accubell® 709 Evo features an internal canister system. Driven by a servomotor, the piston doses paint to the rotary bell. The high-voltage charge attracts waterborne paint to the grounded part, dramatically improving transfer efficiency and process robustness.

During painting, a second canister fills with the exact amount needed for the next job (based on color and vehicle type).

When the sprayer docks, high voltage OFF, the filling canister transfers up to 800cc to the sprayer canister in seconds. A few more seconds are needed to clean interfaces before releasing the sprayer for the next vehicle.

Both electrostatic charging technologies improve transfer efficiency and create a wrapping effect on edges.

External charge works by generating ions that attach to droplets formed by the rotary bell cup system. These charged droplets are attracted to grounded parts, which can unfortunately include the sprayer itself.

In contrast, internal charge acts before droplet formation. The sprayer head repels droplets using its internal charge, offering better protection against contamination.

External charge is more sensitive to humidity, airflow speed, application distance, and part geometry compared to internal charge.

The Accubell® 709 Evo system includes the sprayer, cleaning box, color-change block, and dosing unit.

By comparison, an external charge setup requires multiple components: PPH 707 EXT, color-change block, paint regulator, gear pump, pressure sensors, and an electric motor with driver.

The Accubell® 709 Evo is only 30% more expensive than the PPH 707 EXT, but delivers 7–10% higher transfer efficiency.