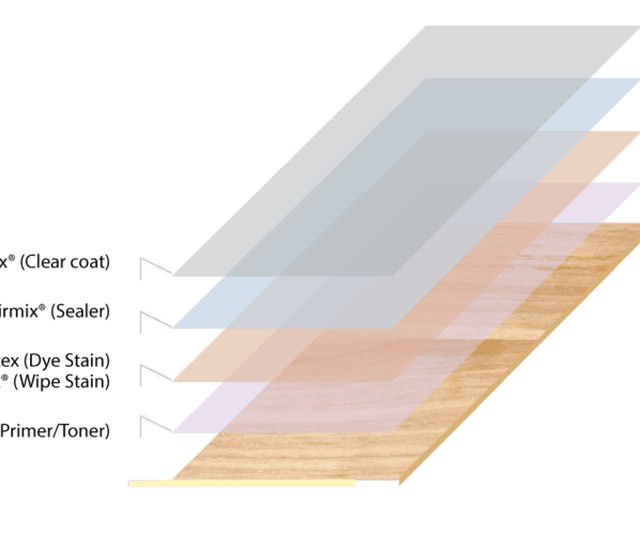

Solid wood process application

DYE STAINS

Applying stain to wood improves the appearance by highlighting the veins, unifying the tone difference and reducing the risk of color changing over time. The most popular wood varieties are enhanced with stains. Stain is applied only to solid wood; never to MDF or particle board. Our Airspray product range will deliver the best finishing results possible!

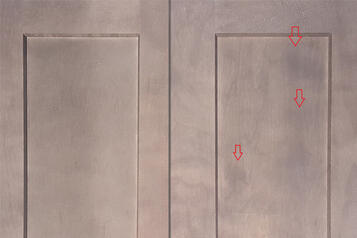

This issue appears usually on flat surfaces when the stain particles in the spray pattern are not homogeneously dispatched.

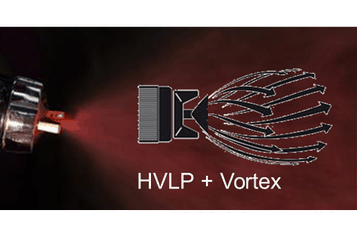

To solve any blotching effect, we recommend using HVLP Airspray combined with VORTEX and RESTRICTOR:

- For manual application: The FPRO® Airspray manual spray gun with Restrictor and Vortex.

- For automatic application: A35 Airspray automatic gun or A29 Airspray automatic gun with Restrictor and Vortex

This issue, which appears in complex-shaped areas such as edges or corners, results from a barrier created by the spray air that prevents the stain particles from covering the edges.

To solve any halo effect, we recommend using HVLP Airspray combined with VORTEX and RESTRICTOR:

- For manual application: The FPRO® Airspray manual spray gun with Restrictor and Vortex.

- For automatic application: A35 Airspray automatic gun or A29 Airspray automatic gun with Restrictor and Vortex

This issue appears when the spray pattern is unbalanced. Stain particles are more concentrated in certain areas of the spray pattern which creates a stripe on the part.

To solve any striping effect, we recommend using HVLP Airspray combined with VORTEX and RESTRICTOR:

- For manual application: The FPRO® Airspray manual spray gun with Restrictor and Vortex.

- For automatic application: A35 Airspray automatic gun or A29 Airspray automatic gun with Restrictor and Vortex

This issue usually comes from a difference in the quantity of stain applied on 2 different parts of a same final product.

To solve any color matching effect, we recommend using HVLP Airspray combined with VORTEX and RESTRICTOR:

- For manual application: The FPRO® Airspray manual spray gun with Restrictor and Vortex.

- For automatic application: A35 Airspray automatic gun or A29 Airspray automatic gun with Restrictor and Vortex

Applying stains in the WOOD INDUSTRY with pressure airspray guns may lead to blotchy effects that need costly and time consuming reworking!

Why? The new FPro® with its newly developed Restrictor and Vortex technologies allows for:

- a good access to parts with recessed areas (thanks to the Vortex effect)

- a perfect film built-up with no blotchy effects (thanks to the Vortex effect)

- a quick application in less passes

- a minimum overspray leading to better working conditions and reduced booth maintenance (thanks to the restrictor effect)

WIPING STAINS

"Shadowing" is a technique used to apply decorative stain by giving an aged appearance. It is the ideal solution for antique-looking wood furniture. After shadows are applied, they are then wiped thoroughly.

This issue comes from an irregular fan pattern resulting from too little or too much stain applied during production.

To solve any inconsistencies of the film build, we recommend to using Airmix® technology

- For manual application: Use the XCITE™ LIGHT AIRMIX® MANUAL SPRAY GUN with our genuine Airmix® tip

- For automatic application: Use the AVX AUTOMATIC AIRMIX® SPRAY GUN with our genuine Airmix® tip

When you need an event layer on solid wood & glossy finishing on MDF, Airmix® technology is particularly recommended for applying clear coat and top coat.

Clear coat and top coat need to have certain thinness. In Airspray, you will need too many layers to achieve the film thickness you need and you will loose lots of paint with the overspray. In Airless® , you will apply too much paint.

Thanks to the low speed of the paint particle and adding 0.5 bar of air atomization, Airmix® keeps a maximum of solvent on the color particle during spraying. The 0.5 bar additional air accompanies the paint particle to the substrate and prevents air movement around the particle so as to avoid “desolvation.” When you spray clear coat or top coat, the solvent aids in smoothing the paint for a glossy and even finish. The avoidance of ”desolvation” along with our Airmix® technology helps in detering orange peel effects.

PRIMERS (UV & NON-UV PRODUCTS)

Primer coats are used between finishing steps to ensure even penetration of stains and finishes, to prevent bleeding of stains and fillers, and to form a good base for the finish. Usually PU, Acrylic, cellulosic, and H2O Primer are used. Only one layer of sealer is needed on solid wood in most cases.

This issue is a result of the trapped inside the film build.

To solve any bubbling effect, we recommend using Airless® Skill technology:

To apply Primer, we recommend using Airless® with Skill technology.

- For manual application: Use the SFLOW™ 275 & 450 AIRLESS® MANUAL SPRAY GUN gun with a Skill Tip

- For automatic application: Use the ASI AIRLESS® AUTOMATIC SPRAY GUN with a Skill Tip

Airless® - combined with Skill Tip technology - is recommended for applying UV paint and primer to solid wood & MDF wood.

When you spray UV paint, the addition of air atomization will create bubbling in the film build during the application. Compared to a classical Airless® application, the Skill Tip technology uses half of the pressure to apply the paint particles, thus limiting desolvation. Bubbling is avoided and a premium finishing quality is achieved.

When you spray Primer, you need to build a certain amount of layers before sanding. The low paint speed of the Skill Tip technology, when compared to a classical Airless® , leads to less overspray and a closer spray proximity to the substrate. This results in a better transfer efficiency and a thicker film build.

VARNISHES

A varnish is applied for cosmetic (gloss, mat) and/or protective (dust, pollution, ultraviolet) purposes to form a colorless, solid film build. Most of the time, varnish is used as the final layer on solid wood. Varnish is transparent and can be applied in one layer.

This issue appears when there is either too much air added to the spray pattern or too much product applied in one layer on the part.

To solve any orange peel effect, we recommend using Airmix® technology:

- For manual application: Use the XCITE™ LIGHT AIRMIX® MANUAL SPRAY GUN gun with our genuine Airmix® tip

- For automatic application: Use the AVX AUTOMATIC AIRMIX® SPRAY GUN with our genuine Airmix® tip

When you need an event layer on solid wood & glossy finishing on MDF, Airmix® technology is particularly recommended for applying clear coat and top coat.

Clear coat and top coat need to have certain thinness. In Airspray, you will need too many layers to achieve the film thickness you need and you will loose lots of paint with the overspray. In Airless® , you will apply too much paint.

Thanks to the low speed of the paint particle and adding 0.5 bar of air atomization, Airmix® keeps a maximum of solvent on the color particle during spraying. The 0.5 bar additional air accompanies the paint particle to the substrate and prevents air movement around the particle so as to avoid “desolvation.” When you spray clear coat or top coat, the solvent aids in smoothing the paint for a glossy and even finish. The avoidance of ”desolvation” along with our Airmix® technology helps in detering orange peel effects.