Battery

Welcome to our World of Battery Innovation

At Sames, we are dedicated to providing cutting-edge solutions for the electrification of cars. As the automotive industry accelerates towards a greener future, our expertise in coating, adhesive, and sealant application equipment plays a crucial role in enhancing the safety, performance, and efficiency of electric vehicle (EV) batteries. Explore our offerings and discover why we are your trusted partner in the EV revolution.

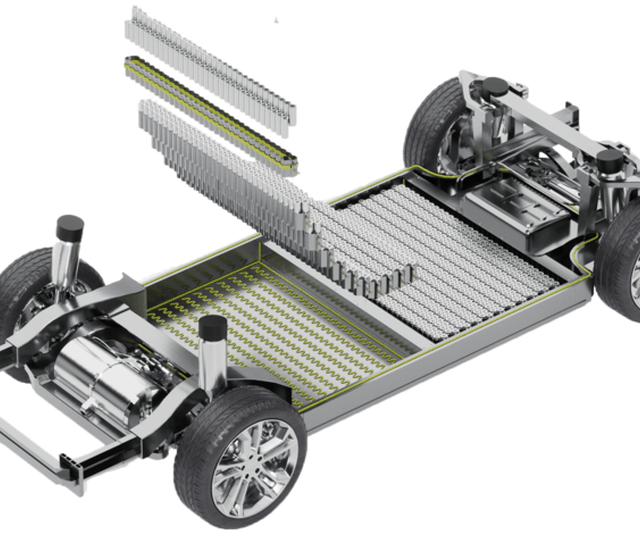

Battery Landscape

Electrification is a race, and Europe is leading the charge. With the EU's commitment to phasing out combustion engines by 2035, the demand for electric vehicles is soaring. Our continent is witnessing the establishment of numerous battery manufacturing facilities, making Europe a global leader in EV technology. This transition not only benefits the environment but also stimulates economic growth and innovation.

Why choosing Sames?

At Sames, we stand out as pioneers in providing solutions for precise and reliable application of materials within EV batteries:

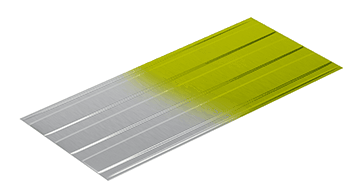

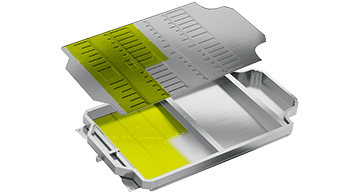

1. Dielectric Coating

Our state-of-the-art equipment ensures uniform and reliable insulation between battery cells, contributing to the safety and performance of EV batteries.

2. Fire Protection

We facilitate the controlled distribution of fire protection materials within battery packs, enhancing safety measures during thermal runaway situations.

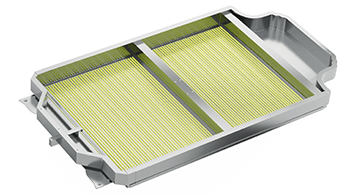

3. Gap Fillers and Thermally Conductive Adhesives

Our equipment enables precise dosing and application of materials for optimal thermal management within the battery pack.

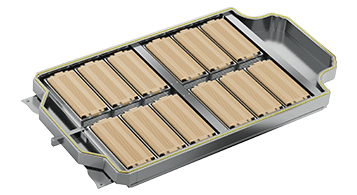

4. Adhesive Applications

We offer precise control and consistency in bonding cells and module frames, ensuring the structural integrity of the battery pack.

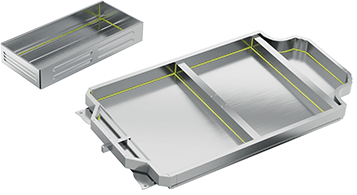

5. Sealing Solutions

Our equipment ensures accurate and uniform sealing, preventing moisture and contaminants from compromising battery pack durability.

With a commitment to quality, safety, and efficiency, Sames plays a pivotal role in the electrification of cars.

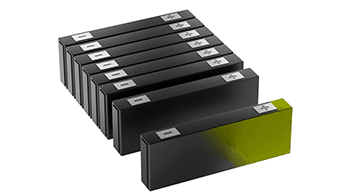

Solution to dispense adhesive on cells :

Solution to spray an even thickness of dielectric coating:

According to your material and cycle time process, please choose the right solution for structural bonding:

1) 1K Acrylic PU with 1K High viscosity with solution C

2) 1K Epoxy PU, Cyanoacrylate, MS Polymer with 1K High viscosity with solution D

According to your material and cycle time process, please choose the right solution for Fire Protection:

According to your material and cycle time process, please choose the right solution for Gap filler or Thermal conductive adhesive:

1) 1K Silicon PU, Epoxy, MS Polymer with solution F

2) 2K Silicon PU, Epoxy MS Polymer with solution G

According to your material and cycle time process, please choose the right solution for enclosure sealing:

1) 1K Acrylic Silicon with solution C

2) Butyl with solution E (soon available)

Solution to dispense sealant beads or spray sealant coating: