Spraying

High viscosity spray

Process by which the compressed material is sprayed allowing an application at a greater distance from the work piece. The width & amount of product dispensed depends on the nozzle type used, the material temperature, viscosity, rheology, and the pressure applied.

The spray will highly depend on the pressure management and the environment conditions.

With stable environment, the quality of the spray will be good.

The challenge in robotic spraying applications is that it must be perfectly managed.

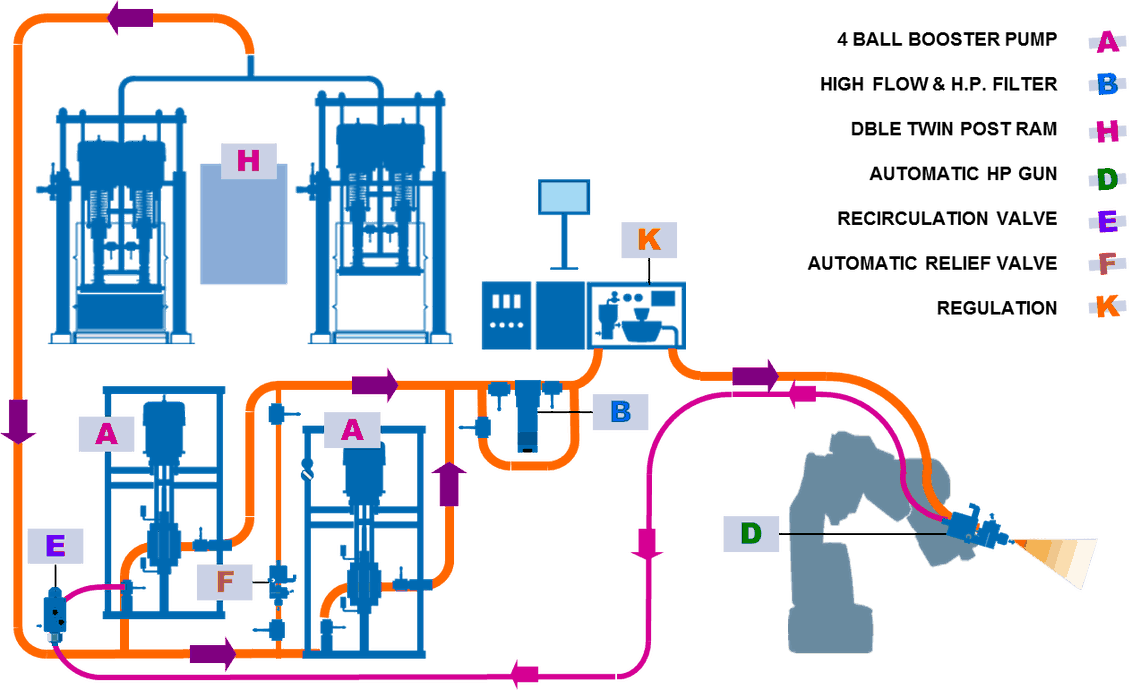

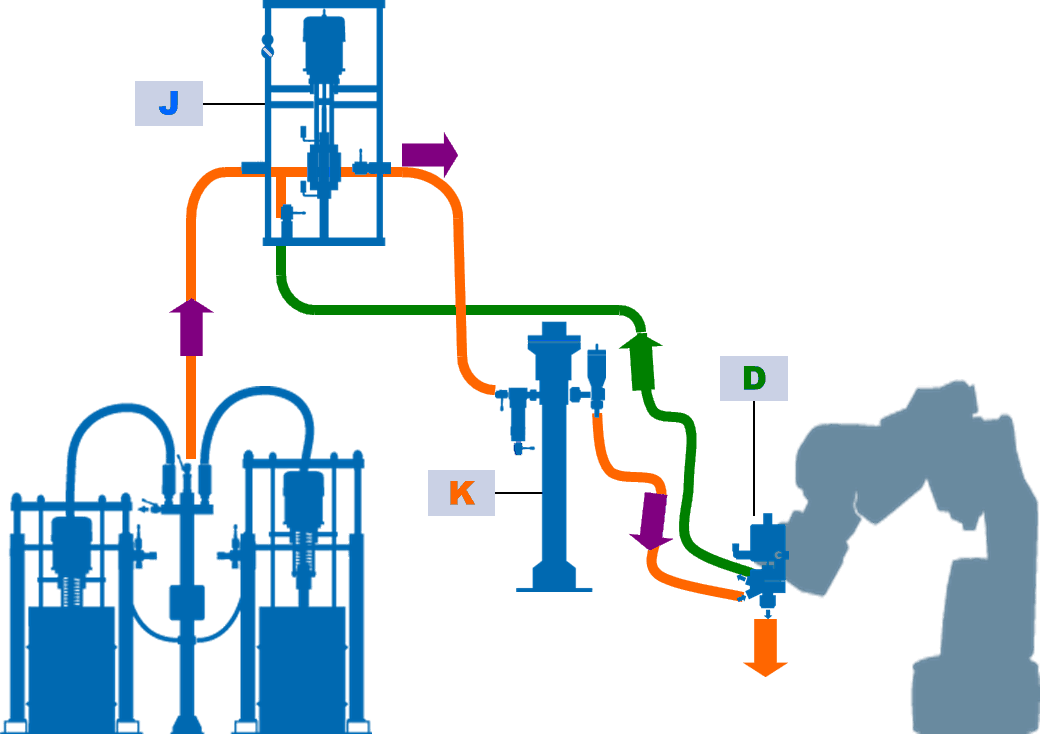

The minimum is to get a recirculation loop, allowing to start and stop the spray with fresh product, at the right conditions.

Recirculation loop for HV Spraying

In the most demanding cases, we will use double supply system, each having a recirculation loop, with a close loop regulation on the material flow. Temperature control can also be included to manage perfectly the spray conditions and make sure that the material is delivered perfectly to the part.