2K solution by mechanical dosing

.

Complete Solutions to Ensure

PERFORMANCE

- Perfect sealant mixing at the head of the gun

- Material losses reduction

- High flowrate up to 13L/min

- Important material pressure up to 500 bars.

PRODUCTIVITY

- High production capacity with 200L drum

- No need to change settings at each production start

- Balanced output pressure with limited reverse effect

SUSTAINABILITY

- User fatigue limit with trigger air assisted gun and balancer

- Remoavble static mixer for fast maintenance operation

- Easy maintenance access thanks to external valve

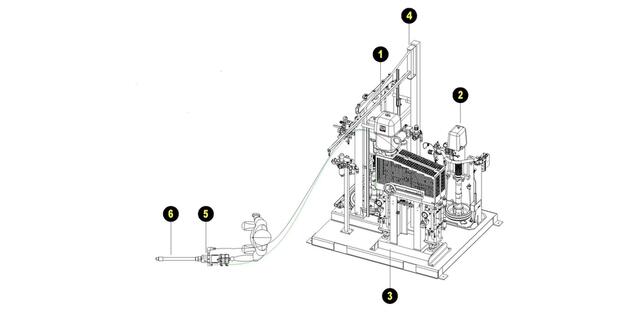

Concept Layout

(1) Base chop check pump

Thor unit on elevator

(2) Hardener chop check pump

Thor unit on elevator

(3) REXSON P85

Mechanical dosing unit with viariable dosing ratio

(4) Grid & Balancer

To limit user fatigue

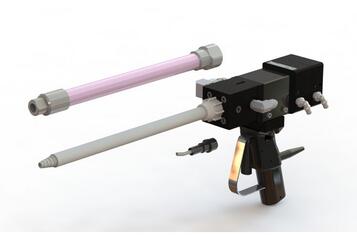

(5) 2K DISPENSING GUN

Available with disposable static mixer or stainless steel

Material A and B meets at the gun head inside the static mixer.

(6) Static mixer

Modular conception

This conception is modular and fits all your needs to:

- Work at longer distance from the dosing machine

- Implement the mixing function on a luge standing on the floor and one mixed material delivering sealant to the applicator

- Use different pump size depending on material characteristic