► How do I adjust my airless spray gun?

Sames SFlow™ AIRLESS pro manual spray gun...

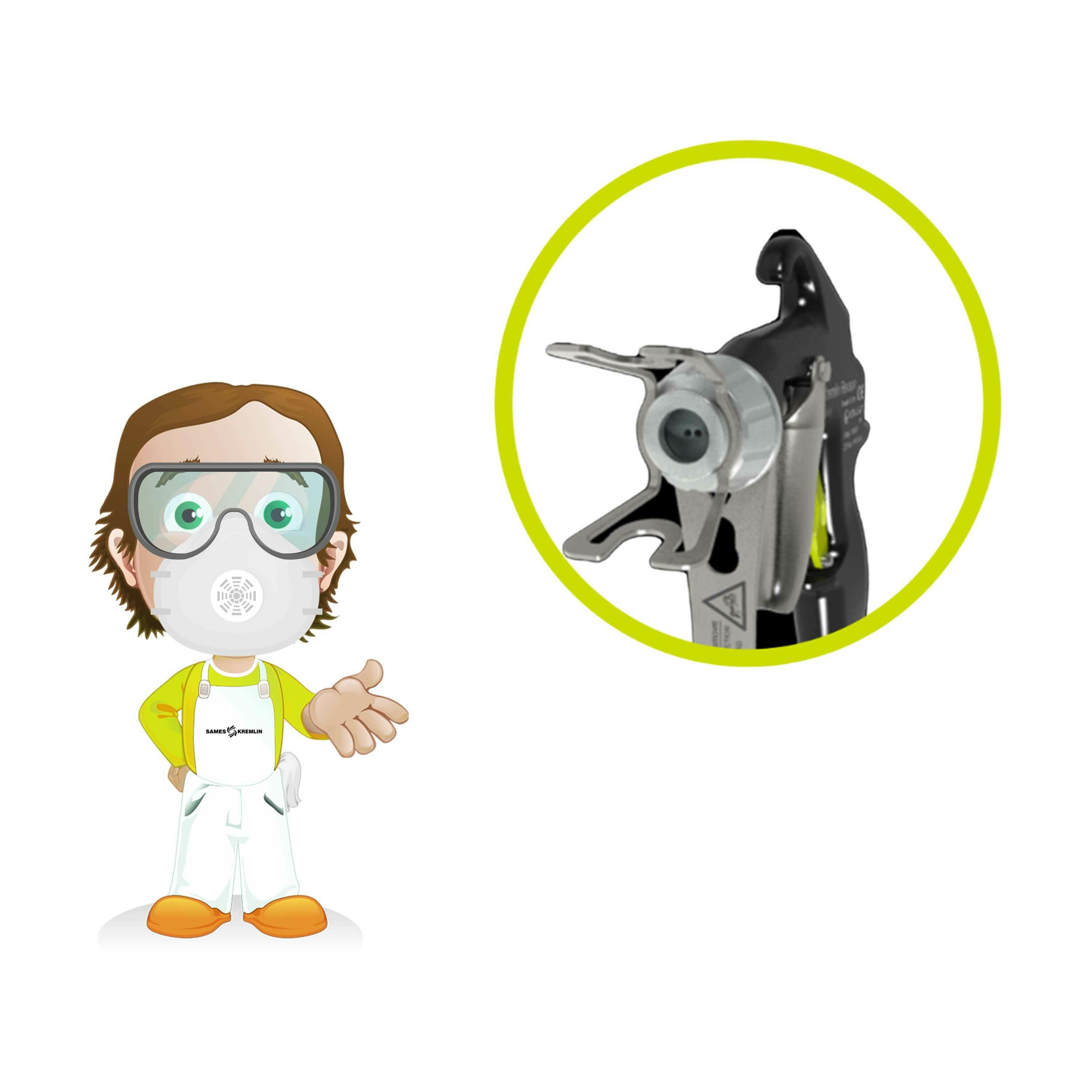

Our SFlow™ spray gun is a high efficiency AIRLESS manual spray gun for a professional painter use only. There are two versions of the gun based upon the working pressure (275 bar / 3989 psi or 470 bar / 6820 psi). The SFlow™ gun is a swivel fitting gun. It is recommended for a wide range of 1K and 2K components of both water & solvent based., high solid materials, epoxy, Polyurethane, anti-corrosion, anti-fouling. It is also recommended for glazing, finishing enamel, acrylic paint materials, front coatings, latex, expanding materials. (Our professional tool is fed by compressed air, when other as Graco Magnum, titan, Wagner, propose electric turbine or hvlp units for diy home projects)

The AIRLESS spraying enables to make material flow through a tip, at high pressure with a long hose length without any atomizing air. The tip is designed to break up the paint evenly into a fan-shaped spray pattern of tiny droplets. Using different tips, you can spray thin liquids like stain, lacquer and varnish or thicker liquids like latex house paint. The gun is supplied with material by means of only one fluid flexible hose.

Airless sprayer is particularly well suited for large paint jobs and since an airless sprayer pumps paint directly from a can or 5-gallon bucket, you can apply a lot of material in a short time.

How do I adjust my Airless spray gun:

How do I adjust my Airless spray gun:

To optimize the spraying, the following parameters are requested : viscosity, charges, materials pressure, tip size. The gun is supplied with a material needle that controls the opening and the closing of the seat when triggering the gun. The fan pattern depends only of the tip :

• with flat tips, you obtain a very fine and regular fan,

• with reversing tips, the unclogging is easier.

How do I choose my Airless tip?

Airless spray tips fit into a tip guard on the front of the airless paint spray gun. They’re labeled with a three-digit number like 309 or 517 (these may be the last three digits of a longer model number). Doubling the first digit tells you the spray fan width with the gun held 12 in. from the surface. A 415 tip, for example, would have an 8-in.-wide fan, while a 515 would have a 10-in. fan pattern.

The next two digits indicate the size of the orifice (hole) in thousandths of an inch. Choose a smaller diameter orifice (.009 to .013) for thin liquids like stain or varnish and a larger hole (.015 or .017) for thicker liquids like latex paint. For example, A 411 tip would work well for spraying varnish on woodwork, while a 517 is a good size for spraying large surfaces with latex paint.

Airless pressure is a key factor to take care of!

Proper consideration of the Airless pressure setting when spraying paint with an Airless paint sprayer is a vital point to achieve a high-quality work result . In addition to the surface coverage and the uniformity of the spray pattern, the pressure adjustment also has an effect on overspray formation, paint consumption and the wear and tear of the paint spraying machine, spray gun and the nozzles. Thinner lacquers and paints usually require less pressure to achieve uniform atomization. Thick paint, on the other hand, requires a higher working pressure in order to achieve a high-quality work result (dilution or temperature as well as prolonged storage also affect the viscosity and structure of the material)

Turn on the pump and move the prime/spray lever to the “spray” position. Spray a strip of paint across a piece of cardboard to check the spray pattern. If the spray pattern has tails, the pressure is set too low. Turn up the pressure. After adjusting, if you still notice uneven spray, you have to change the tip and use one with a smaller hole. Also, make sure you change the tip if the pattern of spray is round.

How does too little pressure affect the spray pattern and the working result?

In the case of paint application with insufficient pressure, the material is not sufficiently atomized and irregularities in the spray pattern can occur. On the wall or on the object, these irregularities are shown in an uneven distribution of the color. In most cases, striping occurs mainly at the upper and lower edge of the spray jet. There, more material is sprayed on, while in the middle area there may be misfires and gaps with insufficient paint application.

How does an excessive pressure affect the spray pattern and the color distribution?

When spraying too high with an airless sprayer, the paint is sputtered too much and accelerated, resulting in unnecessary formation of paint mist and overspray. In addition, the airless device is loaded more heavily than necessary, which increases the wear of pistons, seals and valves. The same applies to the airless spray nozzles used, which are subject to increased wear and tear at higher working pressures. The goal should therefore be to work with the lowest possible pressure setting, but still use enough pressure to obtain a uniform spray pattern.

Do not forget the basics!

And to not forget the basics for a regular application! The gun should be moved parallel to the surface. To prevent run, move the gun fast and If you notice the paint sputtering from the gun, it is perhaps because the tip is clogged. To unclog the tip, twist it 180 degrees. Squeeze the trigger. The most common problems are a leaking pump, clogged tip or clogged filters. Anf you need to use air compressors with a sufficient hp rating.

We recommend you visit our website before shopping for completing your information by reviewing our current catalog. You will find additional information on our painting solutions machines, accessories and products items specifications reviews, warranty and much more!