Aerospace

Why you should choose Sames

- Knowledge and comprehensive process expertise

- Ultimate field service and worldwide proximity support

Composite Process

Spacecraft & satellite construction requires composite manufacturing with controlled processes, such as, infusion, gel coat, bonding, sealing, 2K mixing & dosing, viscosity & pot life controls. We have a wide range of equipment & solutions to build the right process.

Non-Destructive Testing

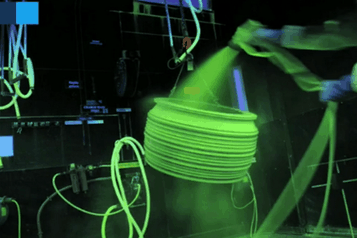

Penetrant testing is a method to Non-Destructive Test (NDT) primarily used in space. This method reveals the presence of discontinuities on any metal, ceramic & composite parts.

Penetrant (from S1 to S4) applied in manual or automatic electrostatic spray:

- Significant penetrant & air savings

- Increased operator comfort

- Easy to maintain

This step is only needed when post-emulsified penetrant has already been applied.

Emusifier can be applied by conventional spraying or with the addition of electrostatic effect.

Electrostatic application of powder developer:

- Very small & regular flow

- Best on the market solution for defect detection

- High transfer efficiency with stable pattern

- 40 years of proven solution for French aerospace OEM