REXSON SH0216 Shovel Pump

- Robust and reliable

- Simple to maintain

- Configurable and versatile

The REXSON pumps of the high viscosity range have been designed with robustness in mind, and the aim of offering a high degree of modularity to follow your application. Unlike liquid fluid pumping, the high viscosity range imposes highly variable mechanical stresses from one product to another.

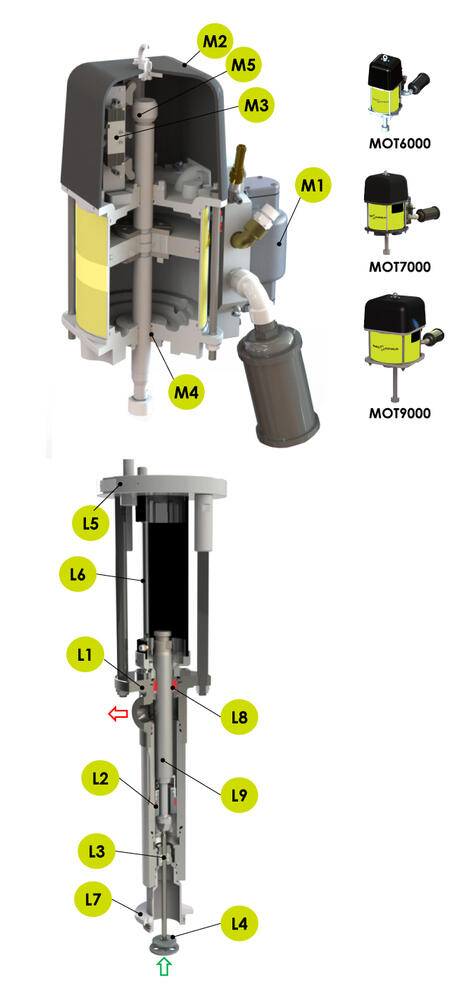

Double-acting shovel pumps are specifically designed to transfer fluid with a viscosity greater than 50,000 Cps and operate from 25,000 Cps for products whose particular rheology makes them difficult to pump. These pumps include a shovel that facilitates feeding the pump inlet, allowing it to move high viscosity materials.

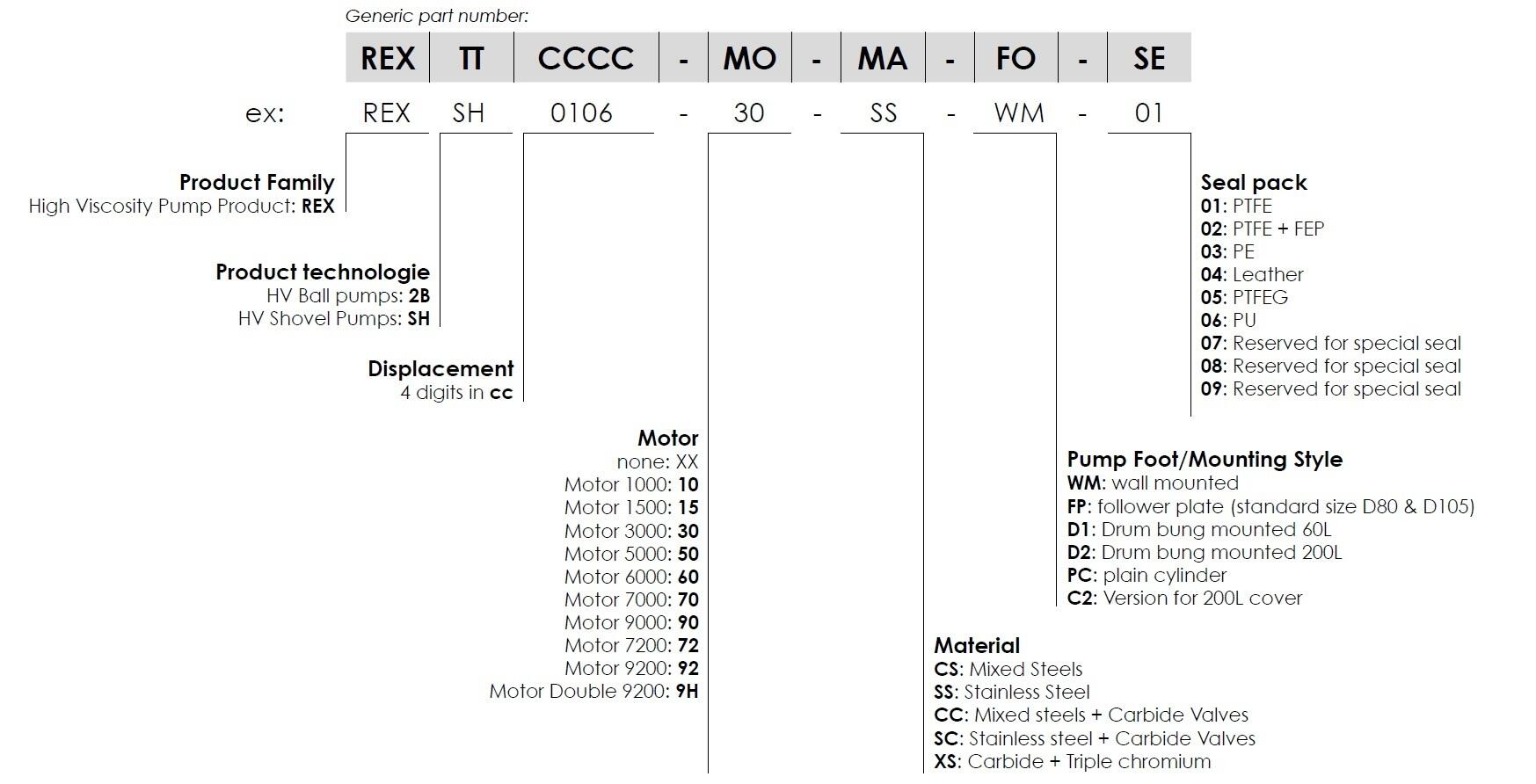

To create your own pump that will meet your application specifications, you will have to select:

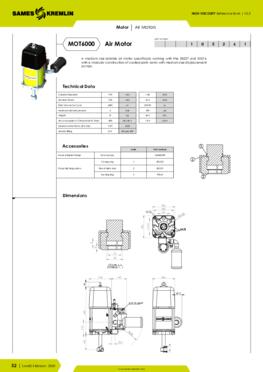

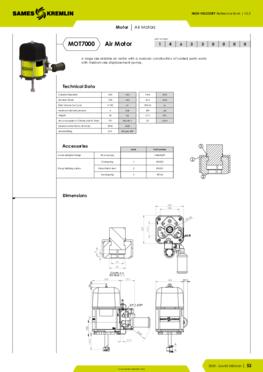

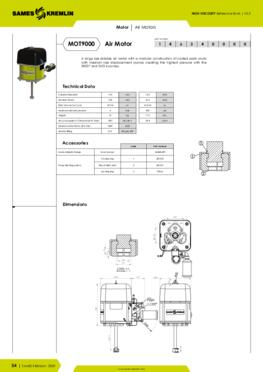

Our air motors are designed for maximum airflow with a pilot distributor to allow fast inversion. They are equipped with a large silencer to avoid water freezing at the motor outlet and can be controlled (start/stop) from a remote air control.

These pumps are used as feeding equipment directly from open drums installed on a elevator using a follower plate.

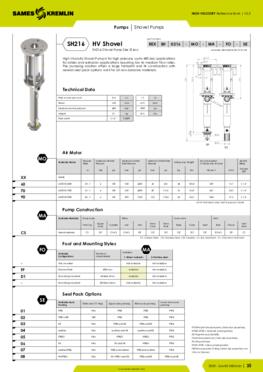

High Viscosity Shovel Pump used for Airless® and extrusion applications. The pumping solution offers a small to mid-size footprint and its stainless-steel construction and different seal pack options work for all materials, including abrasive.

You can customize your pump with the right air motor size and create your own part number. We suggest you contact our experts to help you select the right configuration to fit your needs. You can also consult our Documents tab, our Configurator, and the complete catalog.

| Designation | Value | Unit: metric (US) |

|---|---|---|

| Maximum Fluid Pressure | 480 (7,000) | bar (psi) |

| Maximum Air Pressure | 6 (87) | bar (psi) |

| Viscosity | >50,000 | cps |

| Pressure Ratio (depending on air motor size) | 30:1, 53:1, 82:1 | |

| Maximum Temperature | 80 (176) | °C (°F) |

| Fluid Volume per Cycle | 216 | cc |

| Fluid Output at 15 cycles / mn | 3,24 (0.85) | l/mn (gal/mn) |

| Fluid Output at 60 cycles / mn | 12.96 (3.42) | l/mn (gal/mn) |

| Motor Type | 6000, 7000, 9000 | |

| Air Inlet | 3/4"BSPT(F) | |

| Fluid Outlet | 3/4"BSP(F) | |

| Weight (fluid section only) | 27 (59.5) | kg (lbs) |

| Weight (air motor only) | 21-35 (46.3-77.2) | kg (lbs) |

| Fluid Inlet (follower plate) | 80mm | |

| Air Consumption upon air motor size (see catalog) | --- | |

| Stroke | 120 (4.72) | mm (inch) |

| REXSH0216-MO-MA-FO-SE | Motor (MO) | Material (MA) | Foot (FO) | Sealing (SE) | Model |

|---|---|---|---|---|---|

| ● Motor choices (Pressure ratio) | MO=? | ||||

| - Motor 6000 (30:1) | 60 | MO=60 | |||

| - Motor 7000 (53:1) | 70 | MO=70 | |||

| - Motor 9000 (82:1) | 90 | MO=90 | |||

| ● Lower Material selection | MA=? | ||||

| - Mixed Materials | CS | MA=CS | |||

| ● Foot selection | FO=? | ||||

| - Follower plate (Ø=80mm) | FP | FO=FP | |||

| - Drum Bung mounted (60 Liter Drum / 2'' Bung) | D1 | FO=D1 | |||

| ● Seal package selection | SE=? | ||||

| - PTFE - Polytetrafluorothylene (Teflon like properties) | 01 | SE=01 | |||

| - PTFE + FEP (Encapsulated O-Ring: Teflon like properties over Viton or Silicone) | 02 | SE=02 | |||

| - PE - Polyethene (UHMWPE) | 03 | SE=03 | |||

| - Leather | 04 | SE=04 | |||

| - PTFEG (PTFE + Graphite compound) | 05 | SE=05 | |||

| - PU (Polyurethane) | 06 | SE=06 | |||

| - Leather /PTFE | 07 | SE=07 | |||

| - PU/PTFEV (PTFE + Glass compound) | 08 | SE=08 |

| Description | Part number | |||

|---|---|---|---|---|

| Flat Seal Follower Plate for 20-30L Drums - Ø 280-285 (pump foot Ø80) | 151100100 | |||

| Flat Seal Follower Plate for 30L Drums -Ø 305 (pump foot Ø80) | 151100200 | |||

| Flat Seal Follower Plate for 30L Drums -Ø 315 (pump foot Ø80) | 151100300 | |||

| Flat Seal Follower Plate for 40-60L Drums -Ø 350-360 (pump foot Ø80) | 151100400 | |||

| Flat Seal Follower Plate for 200L Drums -Ø 571 (pump foot Ø80) | 151100500 | |||

| Flat Double Seal Follower Plate for 200L Drums -Ø 571 (pump foot Ø80) | 1055180301 | |||

| Double O-Ring Follower Plate for 20L drum -Ø 280 (pump foot Ø80) | 151101100 | |||

| Double O-Ring Follower Plate for 30L drum -Ø 285 (pump foot Ø80) | 151101200 | |||

| Double O-Ring Follower Plate for 30L drum -Ø 305 (pump foot Ø80) | 151101300 | |||

| Double O-Ring Follower Plate for 30L drum -Ø 315 (pump foot Ø80) | 151101400 | |||

| Double O-Ring Follower Plate for 40-60L drum -Ø 360 (pump foot Ø80) | 151101500 | |||

| Double O-Ring Follower Plate for 200L drum -Ø 571 (pump foot Ø80) | 151101600 | |||

| Double O-Ring PTFE-Coated Follower Plate for 20L drum -Ø 280 (pump foot Ø80) | 151102100 | |||

| Double O-Ring PTFE-Coated Follower Plate for 30L drum -Ø 285 (pump foot Ø80) | 151102200 | |||

| Double O-Ring PTFE-Coated Follower Plate for 30L drum -Ø 305 (pump foot Ø80) | 151102300 | |||

| Double O-Ring PTFE-Coated Follower Plate for 30L drum -Ø 315 (pump foot Ø80) | 151102400 | |||

| Double O-Ring PTFE-Coated Follower Plate for 40-60L drum -Ø 360 (pump foot Ø80) | 151102500 | |||

| Double O-Ring PTFE-Coated Follower Plate for 200L drum -Ø 571 (pump foot Ø80) | 151102600 | |||

| Monocolumm elevator for 20 to 60 L. drums (not available in NA/China) | 151080000 | |||

| Monocolumm elevator for 200 L. drums (not available in NA/China) | 151090000 | |||

| Double columm elevator for 20 to 60 L. drums (not available in NA/China) | 151080500 | |||

| Double columm elevator for 200 L. drums (not available in NA/China) | 151090500 |

Format : application/pdf

Size : 212Ko

Format : application/pdf

Size : 232Ko

Format : application/pdf

Size : 229Ko

Format : application/pdf

Size : 225Ko

Format : application/vnd.openxmlformats-officedocument.spreadsheetml.sheet

Size : 458Ko

Format : application/pdf

Size : 6Mo

Format : application/pdf

Size : 3Mo

Format : application/pdf

Size : 3Mo

Format : application/pdf

Size : 3Mo

Format : application/pdf

Size : 3Mo

Format : application/pdf

Size : 2Mo

Format : application/pdf

Size : 465Ko