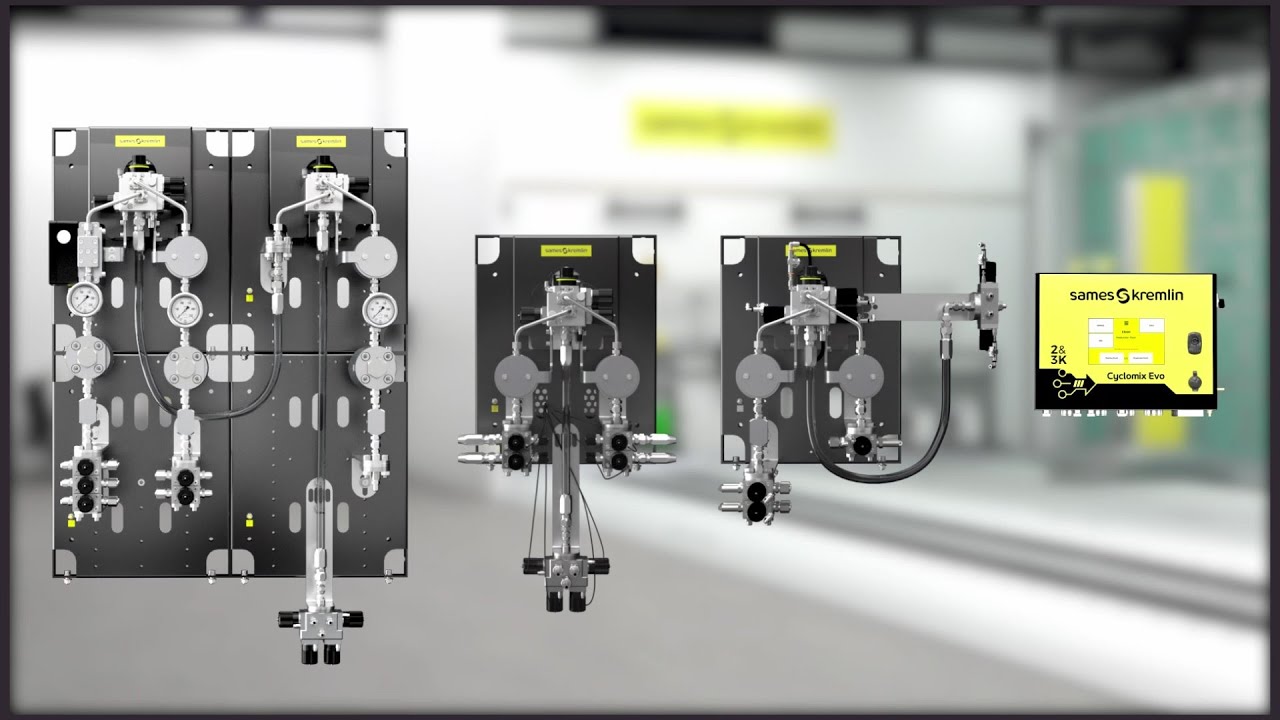

Electronic Mixing & Dosing System - 2 or 3 Components - Airspray, Airmix®, Airless

A patented dosing principle, optimized waste management and connectivity make the Cyclomix® Evo the modular dosing unit that will meet your expectations.

1 Patented dosing system: Spraying the catalyst into the base stream

1 Ultra-fast injection frequency thanks to our new injection valve

♦ Mixing accuracy of +/- 1%.

2 Management of 2 independent circuits: Independent flushing and priming on the 2 circuits

3 Define your own configuration from a basic 2K version to a full options 3K version

♦ 2 minutes of training required for a quick start-up

♦ Buy only the configuration you need. Don't pay for unnecessary features

♦ Increase your production capacity by adding functionalities during the life of the Cyclomix® Evo

♦ Remote diagnostics and maintenance follow-up to avoid any production downtime

4 Reduction of costs and mixed paint waste thanks to the "paint optimization" function

5 Monitoring of production and maintenance data through a smartphone

♦ Retrieve production and maintenance data to optimize your production tool

♦ Perfectly adapted to acid catalysts: Seals, material and threads meeting the constraints of acid or basic products.

| Designation | Value |

|---|---|

| Max. inlet compressed air (bar) | 6.5 |

| Max. inlet compressed air (psi) | 87 |

| Min. inlet compressed air (bar) | 4.5 |

| Min. inlet compressed air (psi) | 58 |

| Recommended Material Viscosity Range | 20 - 3000 in CA4 seconds (or centipoise cps) |

| Maximum Fluid Output (cc/min) | 7000 |

| Maximum Fluid Output (cfm) | 0.25 |

| Minimum Output (cc/min) | 30 |

| Minimum Output (oz/min) | 0.001 |

| Depth (in) | 9.85 |

| Depth (mm) | 25 |

| Depth solution | 20 (control cabinet) - 25 (Fluid panel) for a configuration 4A2B |

| Height (in) | 18.1 |

| Height (mm) | 46 |

| Height solution | 30cm (control cabinet) - 46cm (fluid panel) for a configuration 4A2B |

| Width/depth (in) | 13.8 |

| Width/depth (mm) | 35 |

| Width/depth solution | 40 (control cabinet) - 35 (Fluid panel) for a configuration 4A2B |

| Maximum Material Pressure (bar) | 240 |

| Maximum Material Pressure (psi) | 3480 |

| Weight (kg) | 25 |

| Weight (lbs) | 55 |

| Mixing Accuracy (%) | 1% |

| Mixing ratio | 100:1 à 1:2 (1% à 200%) |

| Number of A Component Solvents (Min/Max) | 99 |

| Number of A Components (Min/Max) | 99 |

| Number of B Component Solvents (Min/Max) | 99 |

| Number of B Components (Min/Max) | 99 |

| Number of C Components (Min/Max) | 99 |

| Number of Components (Max) | 99 |

| Number of Products (base-catalyst-solvent) | 2K, 3K &(1K) base-catalyst-solvent |

| Product Typology Compatibility | Solventbased and Waterbased paint ; Acid catalyst |

| Voltage (V) | 230 |

| Connectivity | Smartphone App (Android, IOS) ; Remote control |

| Display | 7" |

| Robot Communication | Ethernet, Profinet, Modbus, cc-link |

| Traceability | OPCua, USB |

| Air Inlet Fitting | 10 MM |

| Material Inlet Port | 1/2JIC or NPSM |

| Material Outlet Port | 1/2JIC or NPSM |

| Fluid Passages | CTM 2MM INJECTOR STD 1MM |

| Number of circuits | 2 |

| Number of guns (max) | 2 |

| Wetted Parts | FFKM, PEEK, PTFE, Stainless steel 303, Stainless steel 316, Tungsten carbide |

| Additional Technical characteristics |

User management: operator/maintenance/distributor/administrator Manufacturing order number: 12 digits Number of flushing box for manual spray guns: Up to 2 |

| Certification | ATEX II (2) G Ex ia Gb IIB |

| Maximum number of recipes | 250 |

| Designation | Part number |

|---|---|

| MicroEvo Control Panel | 155661890 |

| Flushing box (Fpro, Fstart, Xcite®+, Sflow®) | 155710000 |

| Designation | Part number |

|---|---|

| Short mixer | 155660105 |

| Air feeding kit | 155661391 |

| Clear cover | 155661873 |

| Frame for 3K product plate | 155661870 (x2) + 155661871 (x4) |

| Frame for 2K product plate | 155661870 + 155661871 (x2) |

| Frame for control panel | 155661872 |

| Flushing box (Fpro, Fstart, Xcite®+, Sflow®) | 155710000 |

| Glass kit for in-spraybooth piloting | 155661887 |

| Remote control cabinet | 155661880 |

| Flushbox Waste management | 155661700 |

Powder coating is eco-friendly, durable, and delivers a high-quality, solvent-free finish.