Robotic advanced solution for bonding inner and outer door panels, fronts, and tailgates

In car body construction, the bonding of the inner and outer panels of the doors, as well as the front and tailgate, represents a central process step. Dosing the right amount of adhesive ensures optimum sealing, reliable stability of the body, and the formation of a suitable substrate for the subsequent painting process.

In the hemming bonding process, the inner and outer panels of the doors are joined with adhesive. In addition, the inner panel edge is flanged or folded through the outer panel at an angle of 180° to give the structure mechanical stability.

Two established techniques for applying adhesive are bead and swirl.

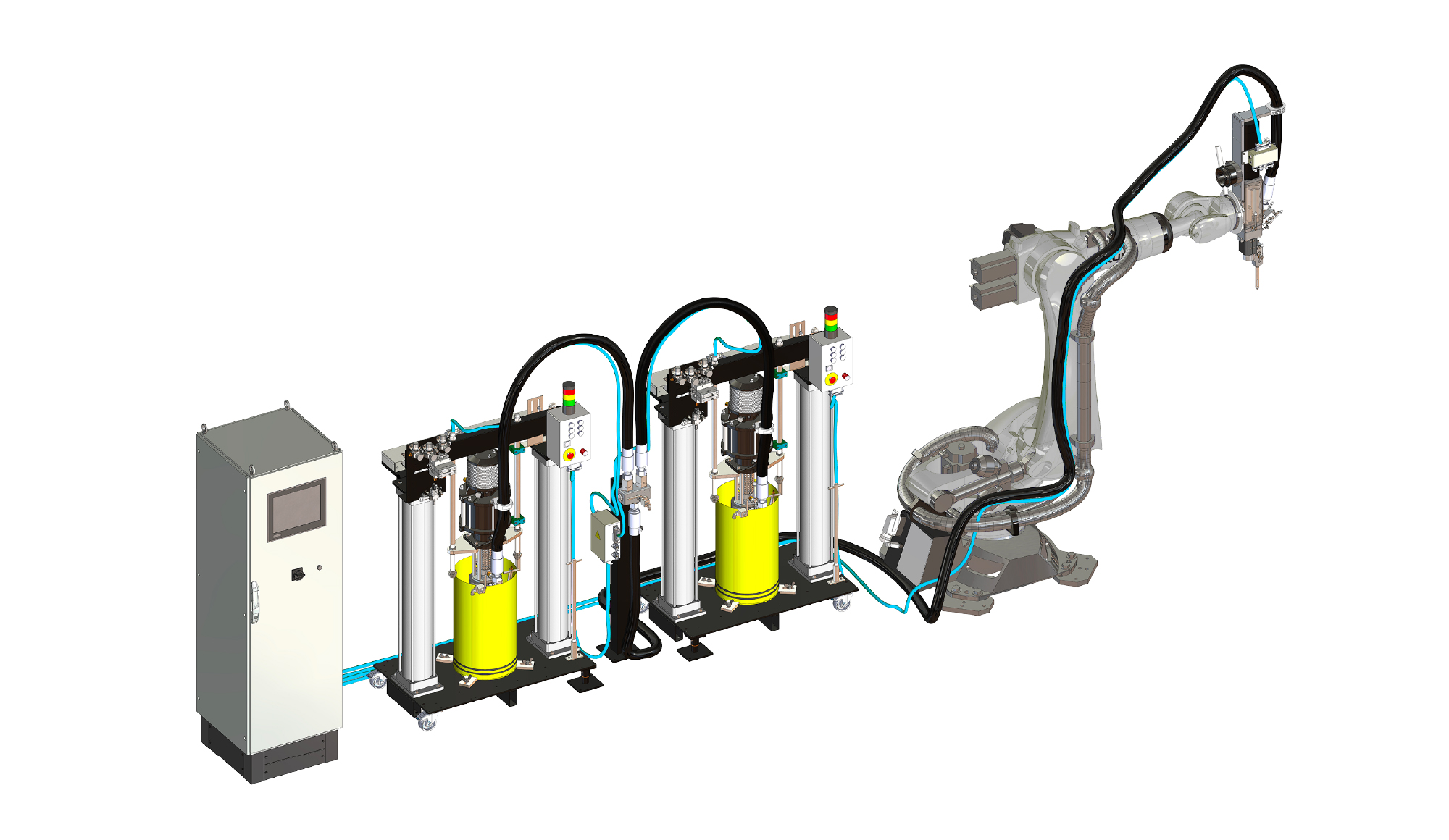

In a standard double-drum system, two powerful ram stations pump highly viscous material from the container. The material then feeds a dosing unit mounted on a robot, which applies bead or swirl patterns to the sheet based on the selected application method.

Turnkey system from feeding to application

Secured process: 2D and 3D self-control camera system

Easy to maintain solution

In bead application, the nozzle-to-component distance is fixed, ensuring the bead cross-section remains constant.

In swirl application, the distance is adjustable, allowing the adhesive width to vary. However, achieving even distribution requires an optimally set width.

Conclusion: