Metallic coil

Let’s talk about your projectAluminum coil passivation by chemical conversion with electrostatic rotary bells

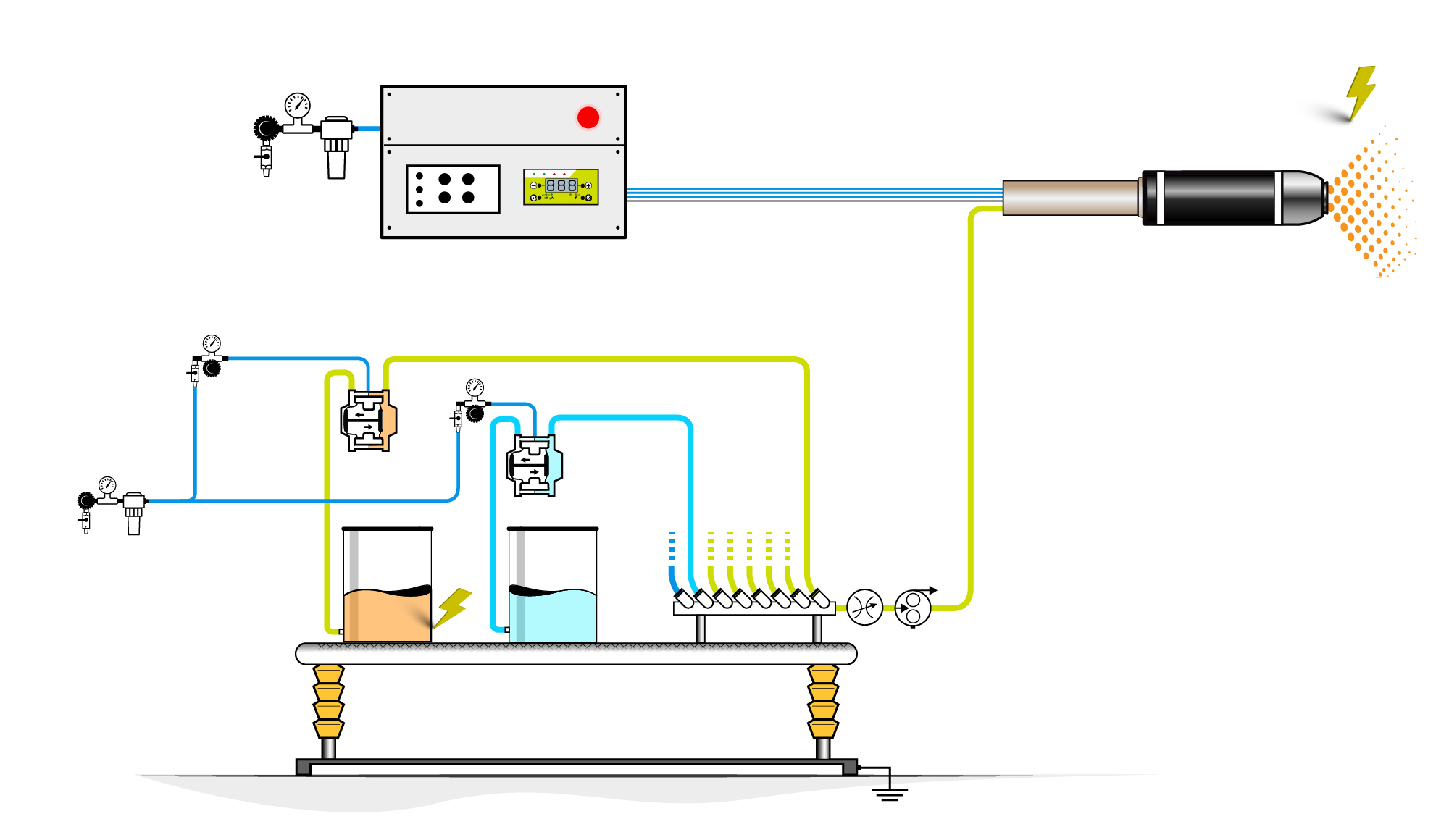

Automatically adjust your settings to achieve a perfect weight deposit 7/7 - 24/24, whatever the coil speed or length, with Sames Nanocoat electrostatic PPH707 chemical bell spraying combined with a continuous supply system of chemical liquid at high-voltage.

Discover our solution

Passivation of aluminum coils uses a chemical conversion process that deposits an acid solution enhanced by salt-induced solubilization onto the coil surface.

Because coil width and speed vary, Sames developed an advanced spraying system that automatically adjusts sprayer spacing and spray parameters in real time, ensuring a consistent deposition rate (g/m²).

This innovation provides complete flexibility—coil width changes without manual intervention or downtime, a major advantage over traditional roll-coating systems.

Components are fully compatible with aggressive chemicals, including hydrofluoric acid. The system features the PPH 707 chemical rotary sprayer, made from a proprietary stainless steel alloy for chemical resistance.

Both automated control and acid-resistant design result from extensive R&D, rigorous testing, and proven field experience.

Trust Sames for a reliable, industry-ready passivation system.

Interactive diagram for information purposes

Main benefits

Efficiency: Achieves up to 35% savings in paint and application time compared to non-electrostatic methods.

Simplify application and achieve a uniform coating with excellent coverage—even on hidden parts—thanks to Sames’ powerful electrostatic effect.

Metallic coil solution FAQ

Let's get in touch-

Which chemicals can be sprayed using the chemical version of the Sames PPH 707?

Aluminum coil passivation uses a chemical conversion process that deposits an acid solution enhanced by salt-induced solubilization onto the coil surface.

Because coil width and line speed vary, Sames developed an advanced spraying system that automatically adjusts sprayer spacing and spray parameters in real time, ensuring a consistent deposition rate (g/m²) under all conditions.This innovation provides complete flexibility, allowing coil width changes without manual intervention or downtime—a major advantage over traditional roll-coating systems.

Components are fully compatible with aggressive chemicals, including hydrofluoric acid. The system features the PPH707 CHEMICAL rotary sprayer, built from a proprietary stainless steel alloy for chemical resistance.Both automated control and acid-resistant design result from extensive R&D, rigorous testing, and proven field experience.

Trust Sames for a reliable, industry-ready passivation system. Contact us to learn more. -

What is the accuracy of salt deposition amount?

Ti/Zr deposition 4-20 mg/m² (WFT ~ 3 µm) with +/-20% accuracy whatever the coil width (0.8-2.2 m) and speed (10-100 m/min)