High-performance spray solution for anti-reflective sol-gel coatings

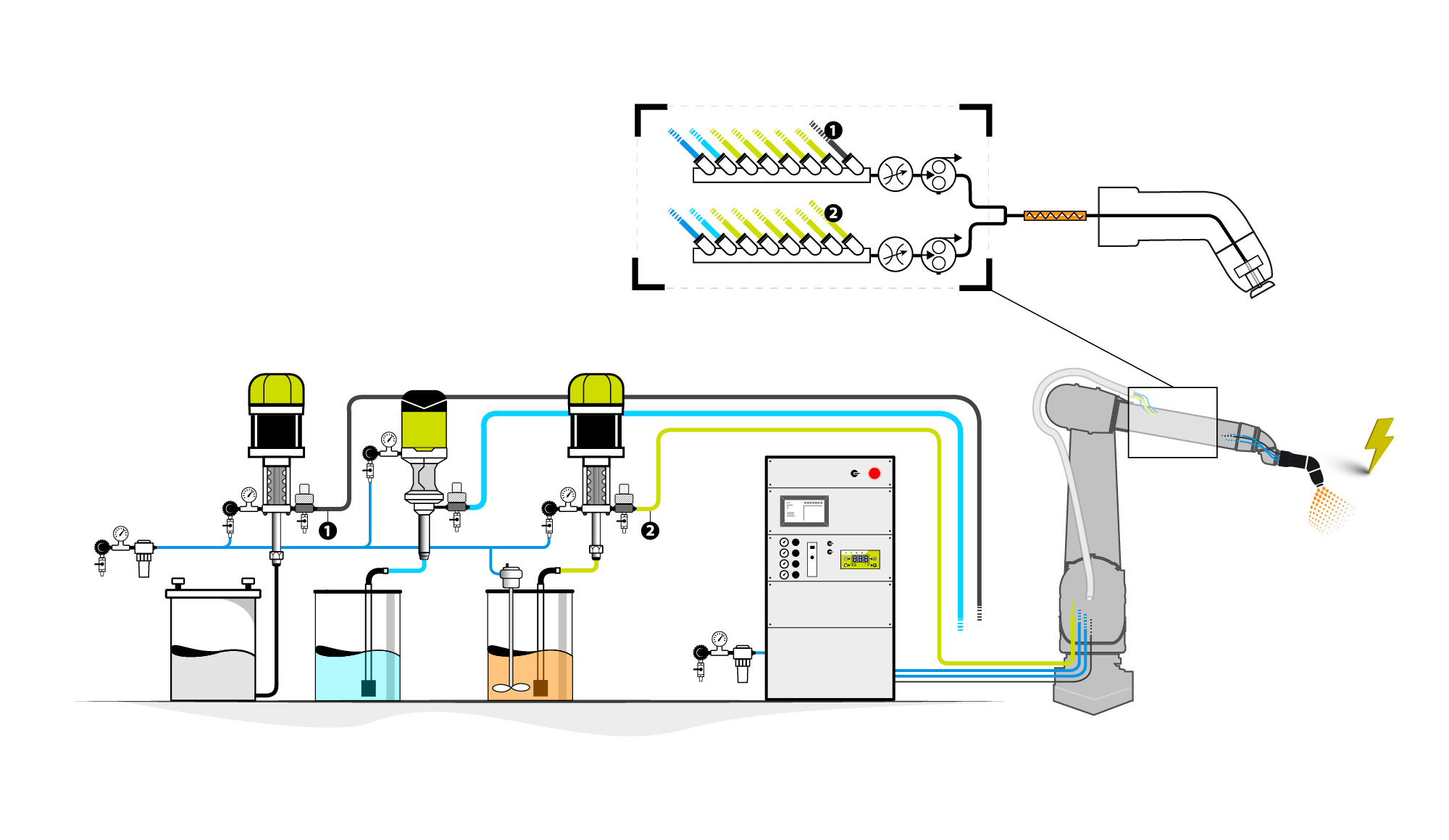

Save up to 50% of sol-gel compared to the dipping process, coat selective surfaces, and obtain the right optical performance or highly reproducible thickness with Sames Nanocoat electrostatic rotary bell spraying combined with a process arm 2K antenna embedded onto the robot.

To meet the growing demand for advanced optical performance in the automotive, photonics, and optics industries, Sames offers an electrostatic spray application solution specially developed for high-performance anti-reflective (AR) sol-gel coatings. This solution is the result of a successful technological partnership with a specialist in sol-gel formulations.

While dipping remains the mainstream method for applying anti-reflective sol-gel coatings offering reliable results for many applications, it can present limitations in certain industrial contexts. The size of the dipping bath naturally restricts the size of the parts that can be treated, and safety considerations linked to the flammable nature of sol-gel solutions can further limit bath volume. Additionally, maintaining chemical stability over time in large volumes requires regular quality checks and generates added cost. Dipping also inherently treats the entire part, which may not always be necessary or desirable.

Selective coating capability: Apply the coating only where needed, reducing material waste and processing time.

Unlimited part size: Free your production from bath size constraints and enable treatment of large or complex surfaces.

High optical quality: Achieve ultra-thin, uniform coatings with reflectance levels below 1.5%, even under 0.9% in some cases.

Industrial productivity: Coat up to 1 m² every 30 seconds with consistent precision and minimal defects.

Sol-gel coatings can bring a wide range of surface functionalities such as anti-reflective, hydrophobic or superhydrophobic, oleophobic, anti-scratch, anti-fingerprint, and even antibacterial properties—making them ideal for high-performance industrial and consumer applications.

Yes, sol-gel spraying is compatible with various substrates, including glass, metals, and transparent polymers like polycarbonate (PC) or PMMA. This opens the door to functionalizing lightweight, complex, or flexible parts that are not compatible with thermal or dipping processes.