2K High volume application - Infinitec

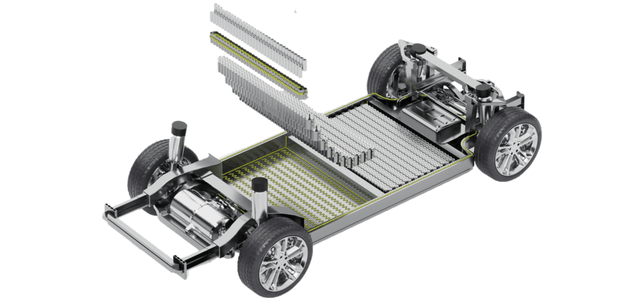

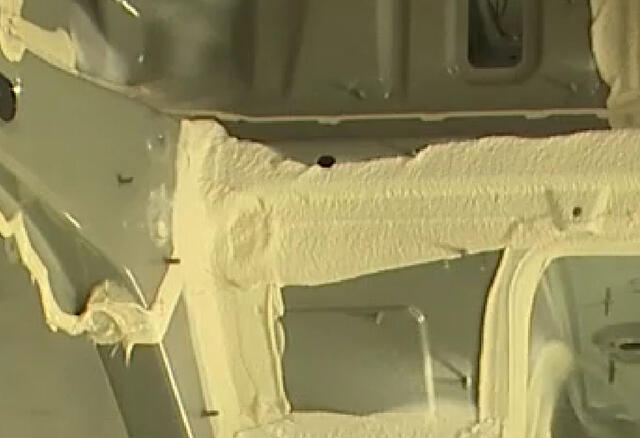

In battery manufacturing, achieving optimal thermal management is critical for performance and safety. One effective solution involves the application of 2K (two-components) materials such as epoxy, polyurethane (PU), or silicones as gap fillers or fire protection materials. These materials not only provide robust mechanical bonding but also enhance thermal conductivity, efficiently dissipating heat generated during battery operation, or the resistance in case of thermal runaway. The use of 2K materials ensures high performance, fast & homogeneous reaction which requires precise application with robust equipment capability.

Which equipment do we offer?

Our dosing units assure best in class precision and accurate dispense for high viscosity applications.

The Infinitec 2K dosing unit ensures a continous application of high flow volumes that eliminates filling times. The robust equipment is based on Rexson pump technology and has been designed 100% inhouse.

Sames Intec pump stations are known for their proven and durable design. The system for conveying high viscosity materials can operate cold or fully heated, with a single or a double barrel system. A large choice of seal packings, pump powers and feeding capacity cover all sorts of applications.

The 2K application head is available with a flat stream or an Airless nozzle. It is able to handle up to 350 bar and disposes of three heating channels. The full carbide needle has a diameter of 8mm.

If you would like to explore our complete range of applications in battery manufacturing, please consult our dedicated market page.