Airless® spraying technology

What is specific to Airless ® Liquid spraying technology?

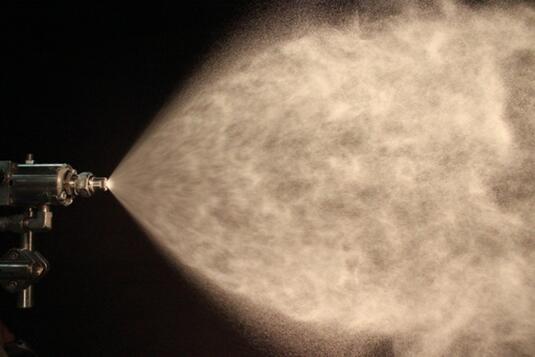

Airless ® spraying happens when the material under high pressure flows through a small hole called a tip. The shape of the hole determines the spraying shape. If the hole is circular, the spray will be round. If the hole is elliptical, the spray will be flat.

The flow rate of a tip (names also as nozzle) depends on the hole surface. The more elongated the hole, the larger the spraying angle will be.

An airless ® spray gun can flow up to 5L / min when operating under optimal conditions, depending on paint job requirements. Airless ® sprayers are designed for big, relatively flat surfaces, such as walls, oil tanks, when HVLP spray gun are, in contrast, ideal for fine finishes.

There are 3 types of tips - FLAT, REVERSIBLE TIP TOP and SKILL for each painter job, depending on the business. Compared to our main competitors (Graco, Wagner, Homeright which commercializes electric Airless® sprayers, titan, tc pro, magnum, truecoat...), our range comprise high efficiency pneumatic airless ® sprayer for big professional projects et smaller jobs.

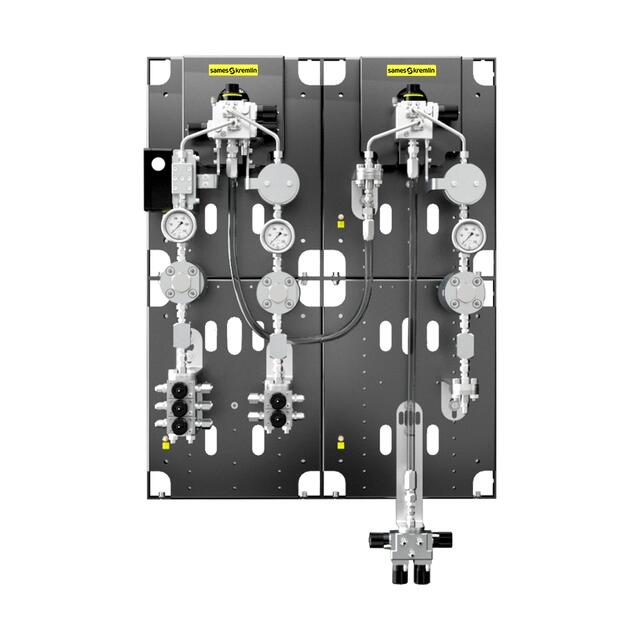

Minimum equipment needed for airless ® spraying:

- A pump with all controls of the pressure

- A high pressure hose

- An airless ® gun equipped with a tip & filter

55 years of expertise in industrial AIRLESS ® technologies!

Which are the advantages of Airless® spray technology?

- Compact design paint spray gun with swivel fittings

- Excellent tip quality - made from the best tungsten carbide worlwide component supplier

- Experts in aircap and tip design for reduced overspray

- Carefully selected high quality materials - as premium stainless steel - for our paint spray gun to ensure a long product life (resistance to chemicals, parts reliability....)

- Guns fed by pump (gravity hopper also available)

- Our cart-mounted airless® paint sprayers can be used by contractors in many markets, benfitting of the gun ergonomy

More on this great tool on our website for brochure download (giving full data description of customer's benefits and specifications) or details on configurations available (wall mounted or mobile versions, packages kits for small business, accessories....) or videos on our Youtube channel! Plus also a quick access to instruction manuals for easy repair and benefit from our expess delivery logistic part posting. (read also see many airless® items on our solution web pages)

What is making Sames Airless ® equipment series so unique?

Our paint airless® sprayers system (kits) includes the SFlow spray gun, equiped with swivel fittting, pumps, hoses and all tools for painting medium to large parts (tubes, containers, cruise ship, walls...). They are available on different configurations, including high efficiency airless® paint sprayers (cart mounted).

The aircap protection guarantees protection safety and skin care of the painter for any painting job, interior or exteriors.

What differentiate our Airless ® paint sprayers?

As a result of a high flow rate from 1.5 to 5L/min with a good finishing quality. Our optimized spray gun built with a confortable trigger makes easy to access every area of parts without any RSI.

Our sytem includes all controls for a perfect application. The SFlow also features a dedicated tool to remove the filter (more details about this tool and how to clean it on our Youtube channel).

Available with Reversible Tip for fast cleaning.

For a wide selection of flow rates & impact width, all build with premium materials which extends life time. Our tip extensions allow to access recessed part areas

Due to lack of air required in the the atomizing process, it is ideal to prevent those issue in industrial business projects..