Pump station Material supply

- Long lifetime

- Easy maintenance

- High standardization

A pump station constitutes the first elementary component in a complete gluing system. Indispensable for maintaining the drums in the right position, it allows an efficient and easy feeding of the material up to the dosing unit.

Sames Intec pump stations are proven for many years and optimized again and again. These are available for drum sizes from 20-200 liters. The systems are available as single or double drum pump stands which are suitable for materials such as epoxy, polyurethane, silicone or rubber based material. Due to their simple design and high level of standardization, they are easy to maintain and have a long service life. The special design of the follower plates guarantees almost complete emptying of the adhesive barrel. Whilst considering a high accuracy in transporting sealants and adhesives, Sames Intec pump stations limit possible dead zones so that material waste can be reduced to a minimum. Optionally, a barcode scanner can be used to check whether the correct adhesive is being used each time the barrel is changed. Furthermore, it allows to verify the shelf-life of the glue.

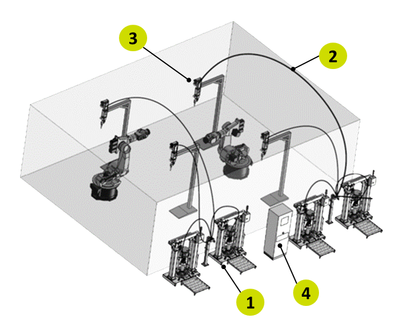

A pump station is part of a complete automated pumping, control and application system. Furthermore, every gluing installation consists of the following components:

(1) A pumping group generally consists of a high viscosity pump which allows to remove the product from the drums in order to feed the distribution at pressures ranging from 100 to 300 bars in general.

(2) A set of heated or unheated high pressure hoses to supply the dispenser with product.

(3) The dosing unit itself can be attached to a bracket or mounted on a robot.

(4) The control cabinet connected to the robot that will interpret the received commands and maintain the proper functioning of the equipment..

Sames offers services to accompany your projects from the technical recommendations to the installation of the equipment. This includes also the process from start-up to the final adjustment. Naturally, the necessary training for use and maintenance is of course provided.

| Designation | Value | Unit: metric (US) |

|---|---|---|

| Maximum Fluid Output | 200 | cc/min (oz/min) |

| Pressure ratio | 50:1 | X/1 |

| Pump displacement | 200 | cc/cycle |

| Fluid output at 10 cycles/min | 2 | l/mn |

| Min. inlet compressed air | 4,5 (65) | bar/psi |

| Max; inlet compressed air | 6 | bar/psi |

| Available drum sizes | 20, 50, 200 (5,2 -13,2 - 52,8) | L/gal |

| Optional heated and unheated version | ♦ | |

| Pneumatic shovel pump | ♦ |

| Designation | Volume (L) | Pressure ratio | Volume per cycle (cc) | Heating | Part number |

|---|---|---|---|---|---|

| Double pump station | 20/30 | 50:1 | 200 | unheated | PD280A0 |

| Single pump station | 20/30 | 50:1 | 200 | unheated | PE280A0 |

| Double pump station | 50 | 50:1 | 200 | unheated | PD355A0 |

| Single pump station | 50 | 50:1 | 200 | unheated | PE355A0 |

| Double pump station | 200 | 50:1 | 200 | unheated | PD555G0 |

| Single pump station | 200 | 50:1 | 200 | unheated | PE555G0 |

| Double pump station | 20/30 | 50:1 | 200 | heated | PD280B0 |

| Single pump station | 20/30 | 50:1 | 200 | heated | PE280B0 |

| Double pump station | 50 | 50:1 | 200 | heated | PD355B0 |

| Single pump station | 50 | 50:1 | 200 | heated | PE355B0 |

| Double pump station | 200 | 50:1 | 200 | heated | PD555H0 |

| Single pump station | 200 | 50:1 | 200 | heated | PE555H0 |

| Designation | Compatibility | Part number | |||

|---|---|---|---|---|---|

| Barrel conveyor | For 200L pump station only | 235060 |