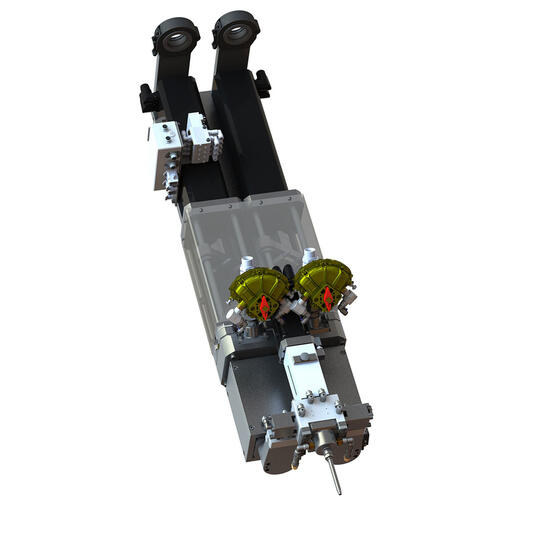

2K mixing head Dynamic

- Compatible with all our dosing units

- Highest accuracy and precision

- Perfect homogeneity at high flow

In comparison to static mixing, dynamic mixing allows higher application flow rates thanks to higher pressures. The dosing units with dynamic mixing are the best in class in terms of precision and cover volumes from 2x50 to 2x400cc. The encoder is able to send more than 250.000 increments per piston stroke millimeter which guarantees a huge accuracy on the flow and the quantity applied. Sames Intec dispensers are thermally controlled to ensure repeatable application in accordance with the recommendations given by the material manufacturers. The design of the dosing chambers is skillfully engineered: its construction realizes a good material renewal and minimizes the required material pressure of the high viscosity material. The First In First Out (FIFO) construction avoids any retention area where the material could harden or degrade and cause the nozzle to block.

All the fluid connections are designed for an optimized hydraulic flow avoiding sharp angles and quick change of orientation. A multiple choice of seals allow an accurate adaptation to the material's chemical compatibility and abrasion. A carbide-carbide sealing solution is available for very difficult materials. The outlet valves are designed for high speed switching and closing at the very end of the nozzle. Thus, you can achieve a very clean and precise application respecting the geometrical specifications of the process. Sames Intec outlet valves offer a large variety of application types: round bead, flat bead, swirl, slot, stitch bead, triangle section, etc. Our shotmeter range has been designed with reliability and quick maintenance in mind. All components are easily accessible and the replacement time has been optimized to make our solution as available as possible for production needs. Furthermore, the capacity of the dosing chamber can be adapted from 2x50cc to 2x400cc according to the volume of applied material thanks to a very easy assembly of the dosing parts.

During dynamic mixing, both adhesive components are simultaneously mixed by a driven helix. Due to the rotation and geometry of the mixer and the chamber, the material mixes optimally for the subsequent application. A cooling system can be added for exothermic reactions.

Sames also offers a 600 and a 1300cc dispenser (L1K).

| Designation | Value | Unit: metric (US) |

|---|---|---|

| Power Supply | 480 | VAC |

| Width | 204 (9.5) | mm (") |

| Depth | 290 (11,4) | mm (") |

| Height | 891-974 (35 to 38.3) | mm (") |

| Air Inlet Maximum | 6 (90) | Bar (psi) |

| Maximum Inlet Pressure | 300 (4350) | Bar (psi) |

| Maximum Outlet Pressure | 135-215 (2000-3120) | Bar (psi) |

| Dispense Volume | 5 - 640 | cc |

| Weight | 60-99 (132-218) | kg (lbs) |

| Max Product Temperature | 80 | °C |

| Max. rotation speed | 1.700 | rpm |

| Designation | Part number | ||

|---|---|---|---|

| 2K dynamic mixing head - Please consult us | ♦♦♦♦♦ |

| Designation | Part number | |||||||

|---|---|---|---|---|---|---|---|---|

| Please consult us | ♦♦♦♦♦♦ |