Cleaning System

Let’s talk about your projectPatented solution specially developed for surface pretreatment to ensure optimal adhesion of the adhesive material to the substrate.

The patented ATMR cleaning system is used for both cleaning component surfaces and applying functional fluids before the application of adhesives and sealants. If grease, oil, or dust residues are present on the component, this can impair the adhesion of the material.

Discover our solution

Unlike conventional cleaning methods with spray technology applied to the component, the advantage of our cleaning system lies in the precise dosing of the cleaning agent into a felt cube.

The intelligent control technology can individually adjust the saturation level of the felt in each component section. This reduces emissions, saves cleaning materials, and limits the functional fluid to the adhesive bead path. For optimal cleaning results, the contact pressure of the applicator on the substrate can be adjusted as needed. The intuitive operation of the system ensures smooth, fully automated production.

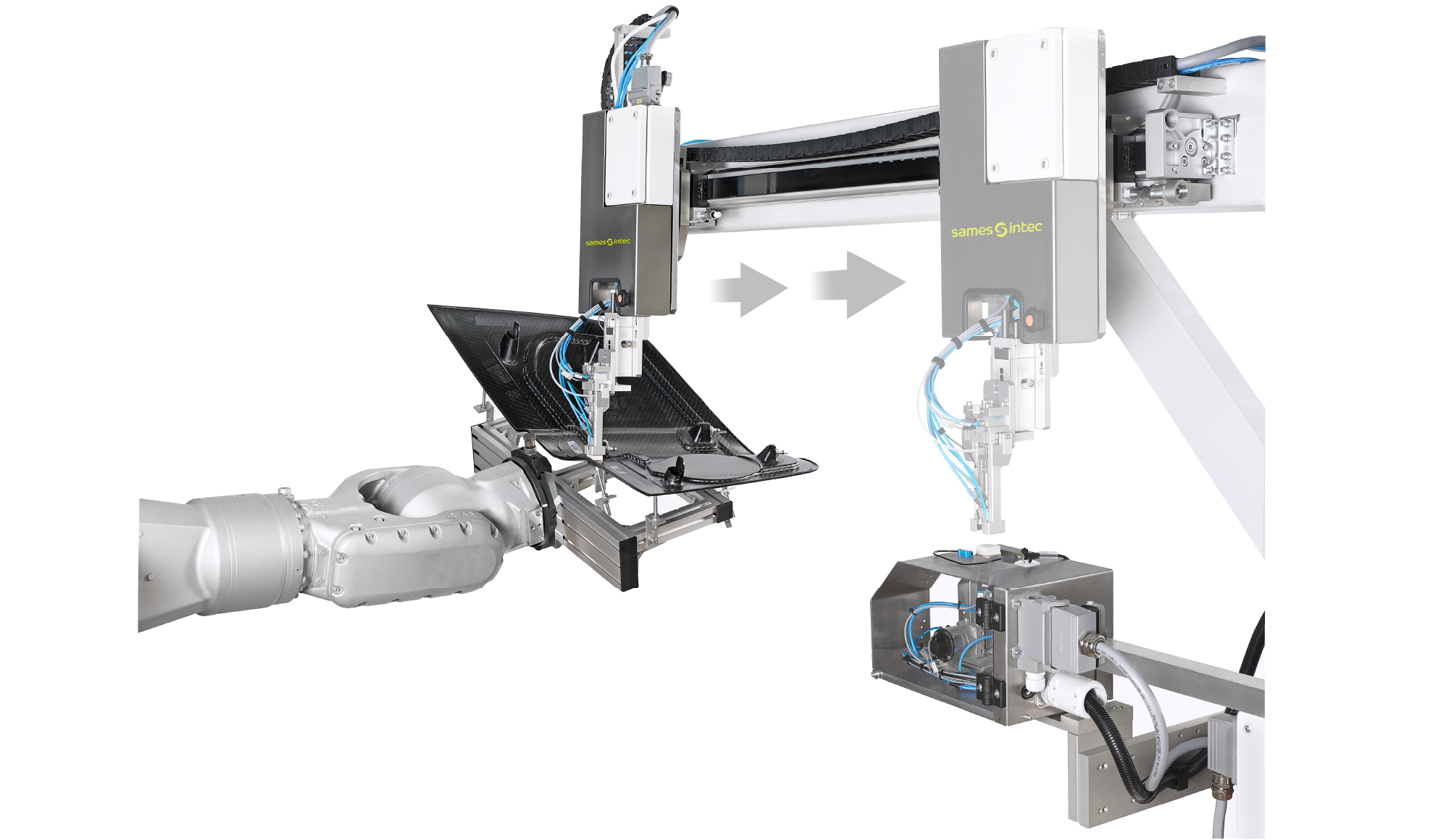

Additionally, the smart design with a modular structure allows for easy integration into your system. Our cleaning system is available in various configurations. For example, you can choose to mount the application head on either a robot or a stand. The felt pieces come in two different geometries (16 mm and 25 mm width). We are happy to advise you on your specific application!

Interactive diagram for information purposes

Main benefits

Precise dosing of the cleaning agent

Smooth, fully automated production

Individually adjusted saturation level of the felt to save material, emission and optimal cleaning.

Tanya Jawab Solusi Sistem Pembersihan

Ayo hubungi kami-

Mengapa harus dibersihkan sebelum aplikasi perekat?

Sisa gemuk, minyak, atau debu mungkin terdapat pada komponen, hal ini dapat mengganggu daya perekat material.Pilihan bahan pembersih tergantung pada jenis polusi yang akan dihilangkan. Sistem kain flanel menjamin efisiensi proses pembersihan: dibandingkan dengan sistem kuas atau semprotan, jumlah bahan pembersih dikontrol secara individual dan posisi jalur diatur oleh robot. -

Apakah sistem ini sepenuhnya otomatis?

Ya, sistem konveyor membawa kain flanel satu per satu ke kepala aplikasi. Kepala aplikasi memungkinkan aplikasi cairan fungsional yang tepat ke permukaan substrat yang telah ditentukan. Ketidakteraturan pada komponen dikompensasi secara efektif dengan penyesuaian ketinggian pneumatik dan tekanan kontak variabel. Jumlah cairan yang diterapkan dapat diatur sesuai kebutuhan dan disesuaikan secara bervariasi.Kemudian, potongan kain flanel yang sudah digunakan dibuang ke dalam wadah pembuangan.Hanya memasukkan kain flanel baru ke dalam pengisi daya, dan mengeluarkan kempa bekas yang merupakan operasi manual untuk tim operator.