Protective coating

Ensure long-lasting corrosion protection in the toughest field conditions with Sames’ high-performance manual Airless solution—combining the robust Azur pump and precise Sflow spray gun for unmatched reliability, efficiency, and finish quality.

In civil engineering, protecting metallic infrastructures, such as bridges, pipelines, and offshore platforms from corrosion is critical to ensure long-term durability and safety. Manual airless spraying is a preferred method for applying high-performance anti-corrosion coatings in demanding field conditions.

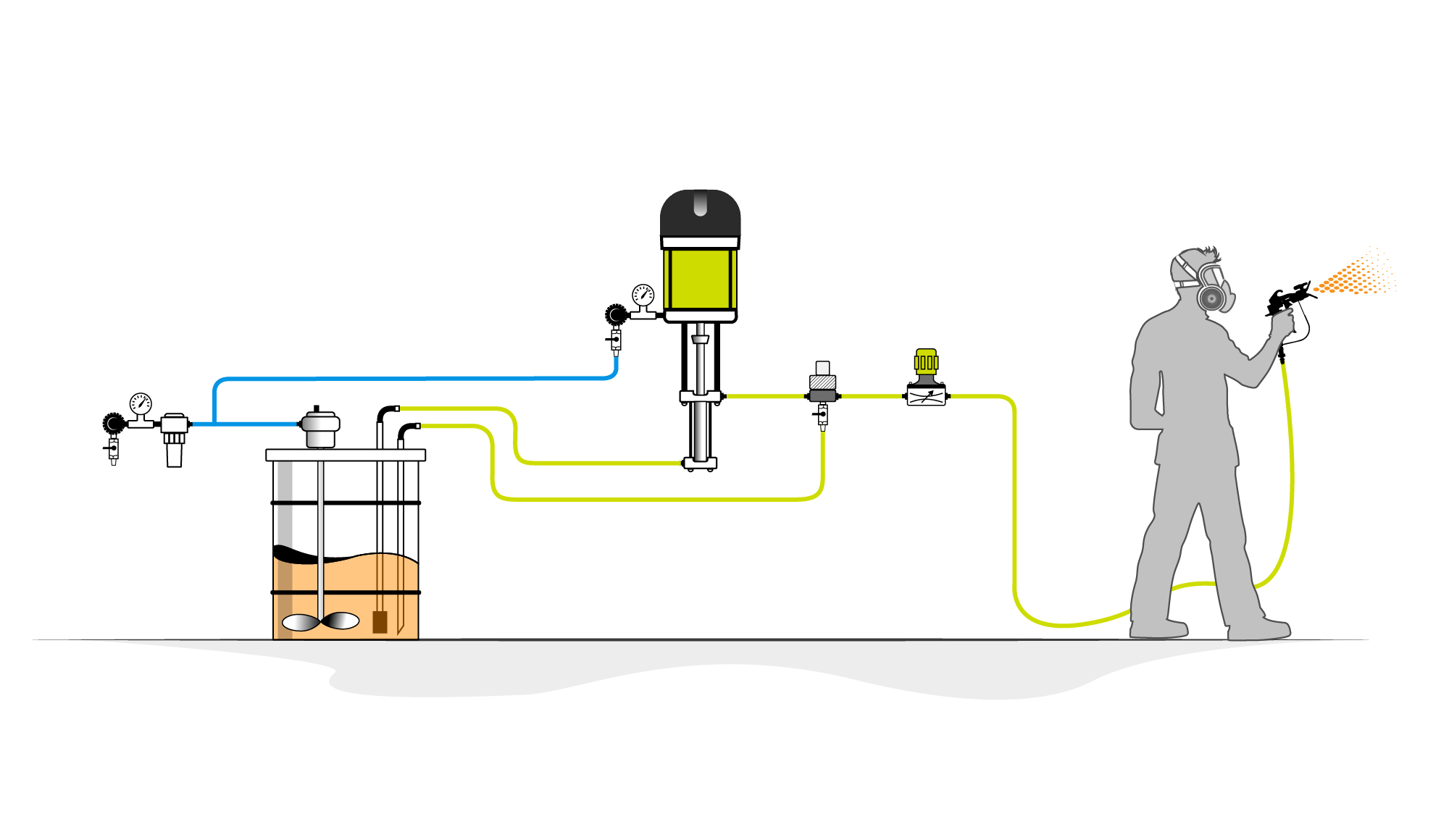

To meet the rigorous requirements of this application, Sames offers a complete manual spraying solution combining the Sflow airless spray gun and the Azur pump. Designed for use with single-component paints, pre-mixed 2K coatings, and zinc-rich materials, this system delivers a high-quality finish with maximum reliability.

The Azur pump is the backbone of this solution, providing powerful and stable material transfer without compromising finish quality. Built for harsh and intensive environments, it ensures uninterrupted operation and consistent performance, even with the most abrasive or high-viscosity protective coatings. Its rugged design, simple maintenance, and user comfort make it the go-to choice for professionals in the protective coatings industry.

Paired with the Sflow gun, which operates at up to 470 bar (6800 psi), applicators benefit from excellent coating control, precise film builds, and a reduction in overspray. The ergonomic design of the Sflow ensures user comfort during long shifts, while maintaining high application efficiency across a wide range of substrate shapes and sizes.

Together, the Azur pump and Sflow gun form a high-performance manual airless solution for on-site corrosion protection, ensuring long-lasting protection and operational efficiency on every project.

Precision Spraying with High Transfer Efficiency: Achieve up to 81% material transfer efficiency and reduce overspray with Sflow’s high-end Tungsten carbide tips.

Use the correct tip type and size for your coating. Sames offers a wide range including Skill® tips, designed for optimal atomization and smooth finishes with minimal overspray. Combine with proper spraying distance and stable pressure from the Azur pump for best results.

Sames combines high transfer efficiency (up to 81%), robust durability, and ergonomic design in its airless technology. The Sflow gun and Azur pump are built for high-performance applications in tough environments, with smart maintenance features and patented tools that reduce downtime and increase operator comfort.

The Azur pump features a powerful hydraulic section and optional 2" suction hose designed to handle materials up to 30,000 cps. It ensures smooth flow without pulsation, making it ideal for spraying thick, high-build protective coatings on metal structures.