EasyMask solution

EasyMask is the first industrial robotic masking solution on the market.

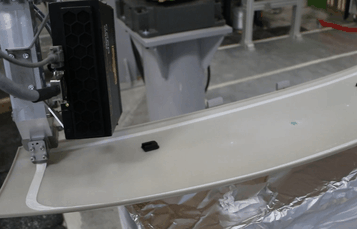

Latest generation of tailgate are made of multi material components, which are joined together with a gluing process.

To secure the adhesive effect, the gluing tape has to be free of overspray of paint. So the outer panel has to be masked before the painting process, then unmasked for joining phase.

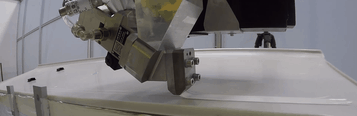

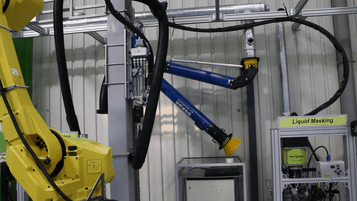

Masking the gluing tape of each panel can now be made by robots !

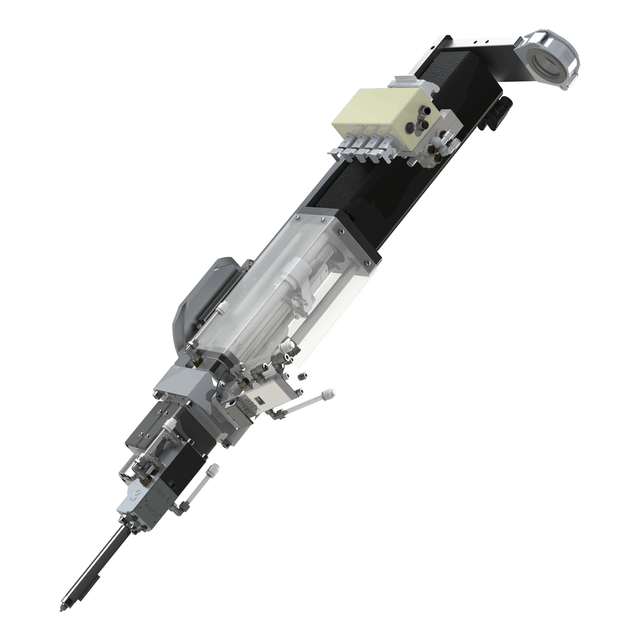

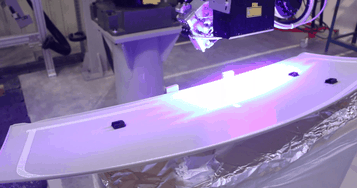

The patented head dispenses viscous material, which dries under the UV lamp effect, and become an elastic ribbon protecting the gluing tape.

After the painting process, the material remains easy to peel off, and the under surface is clean and ready for the gluing process.

Complete solutions to ensure

- Robotic repeatability

- +/-1 mm positionning

- Electric shotmeter for accurate dosing

- Heated supply for steady viscosity

- Automatic cleaning device of application head

- No manual tape application

- Standard industrial robot

- Quick & easy manual removal operation

- Fast robot path

- Up to 60 tailgate /hour /robot

- Up to 120 spoiler /hour /robot

- Dispense and UV cure can be made in parallel

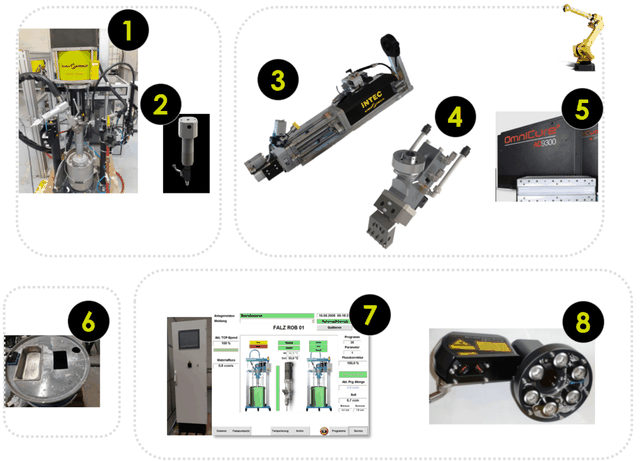

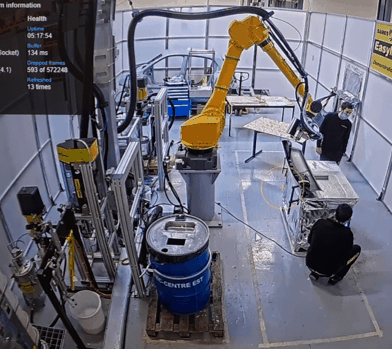

Typical project Package

To locate the part & correct the trajectory

- 100% transfer efficiency - No overspray

- 19mm width pattern

- Thickness between 200 - 500µm, controlled by dosing unit and robot speed

- Automatic nozzle cleaning device

- Flexible trajectory to adapt to a large number of type

- Application on horizontal and verical surfaces

- Vision system to locate the part and correct the trajectory.

- The pumping unit is made of two ram unit, of 63C106 heated pump.

- The electric shotmeter 200cc comes from Bodyshop adhesive application process.

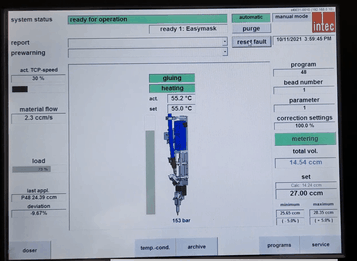

HMI to control :

- electric shotmeter flowrate and refill

- Double Ram unit

- vision system to locate the part

- heated zones

- safety of the cell

EasyMask more in details

The EasyMask solution is composed of Sames's patented dispense head. The uniform thickness of the strip is given by the size of the shim.

The electrical dosing shotmeter iSK, designed for small volume (200cc capacity) gives the constant flow of the heated (55°C) material.

The station has its redundant filtration system after the high pressure pump station, for a 160bar application pressure.

The HMI control, based on home-made software used for Bodyshop adhesive solutions, pilots heating devices, shotmeter refill process, UV lamp for curing and safety barriers around the dispense cell.