2 Balls

Liquid feeding technology

All our pumps are equipped with a pneumatic motor (for power) and a ball hydraulic (driven part). The majority of our pumps are double acting pumps.

Operating principle

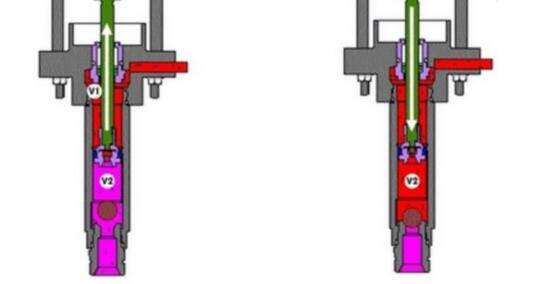

- When a piston down strokes, a suction valve (big ball) is closed against the seat and the material in the chamber (V2) is displaced out of the pump by the pump displacement rod.

- When the piston up-strokes, a suction valve opens and material is sucked into chamber (V2). The exhaust valve (small ball) closes and material is pulled from chamber (V1).

The piston moves on the upper part through a lubricating cup (Cup Lub) to avoid overheating by ensuring continuous lubrication.

because the suction foot valve has a large passage.

because we can adapt the ball material.

with balanced fluid delivery on up and down strokes.

on the lower foot valve.