LASD in PAINT SHOP

Liquid sound deadener (LASD) is now replacing the traditional acoustic damping pads. Water-based LASD is the modern alternative to traditional bitumen mats with significant weight savings.This new material saves weight, reduces costs and stocks along the assembly line. Moreover, utilising a robot gives the flexibility to adapt the dispensed size and thickness of each application, according to the car model and reduce weight. The robotic process allows the pattern to be easily changed to increase the performance of dampening as needed.

Requests from OEMs to have a lower density and more environment friendly material, has seen the LASD manufacturers create a waterborne acrylic material. Achieving 50% of mass reduction compared to pads, this material is also compatible with the energy saving, lower bake temperatures now to used cure car bodies. The challenge in using this new material relates to the pumping and dosing equipment because of its higher viscosity and abrasiveness. Using these wetted materials requires the pumps, regulators and shot meter chambers to be made of high grade of stainless steel, such as those made by Sames. For aluminum car bodies, the vibration modes are shifted to a high frequency (over 300Hz) compared to steel car bodies. The material manufacturers are adapting the chemicals, and the application process needs an accurate dosing process to deliver the most effective dampening performance, with the right thickness and position of the material on the plates.The LASD robotic cell apply on the floor surface of car bodies.

The LASD dampen dramatically noise and vibration of structure panel, for a better comfort of passenger.

Complete Solutions to Ensure

- Flexible & Compact multi-gun head for flatstream

- StreamLoop regulation control based on Sames experience

- Recirculation material : gun to booster pump

- Low investment solution

- Lightweight equipment for high speed robotic application

- Compatible with small robots

- Complete solution from pump to applicator

- High reliability equipment

- Pump range adapts to your flow and pressure requirement

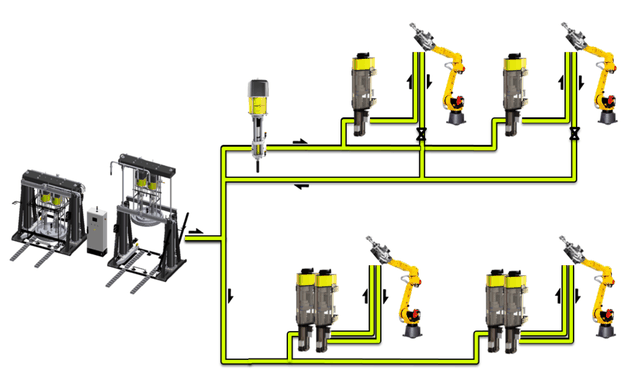

Concept Layout

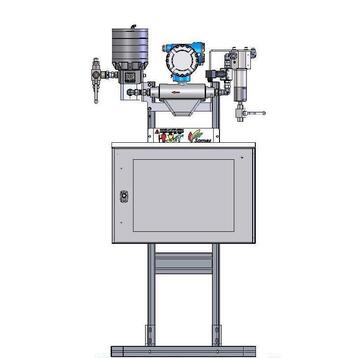

1000 L Folding Accordion shaped Ram unit

- Booster and recirculation pump

- Feeding during up & downstroke

- Symmetrical design for best balance pressure

- Most efficient pump in booster operation

- Fast : Adjust itself continuously

- Robust : Learn from previous job gap

- Accurate : <3%

- Compact & lightweight gun

- Multi-gun available

- Fast and small robot

LASD continuous application

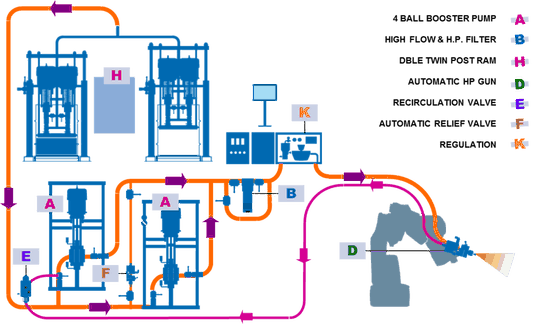

In the case of high volumes to dispense, we can also use a close loop regulation with mass flowmeters.

Our recirculation concept with QUATRO pumps allows to have always fresh material at the gun head with a controlled and stable temperature.

Double RAM units can execute a hiden time changeover to let the production run without stop.

Double QUATRO booster pumps allows to get a higher flow, and to be able to continue dispensing in case of maintenance on 1 pump.

モジュラーコンセプト

このソリューションはモジュール式であり、お客様のニーズに合ったソリューションを提供します:

•幅広いポンプで圧力と流量を調整する

•要求された品質を適用する:スプレー、フラットストリーム

•サイクルタイム、パッチの長さ、品質チェック、

•効率を向上させるためのオプションを追加:ボディ位置決めのためのビジョンシステム、アプリケーションの高品質を維持するための温度制御。