Automotive solution - Plastic parts

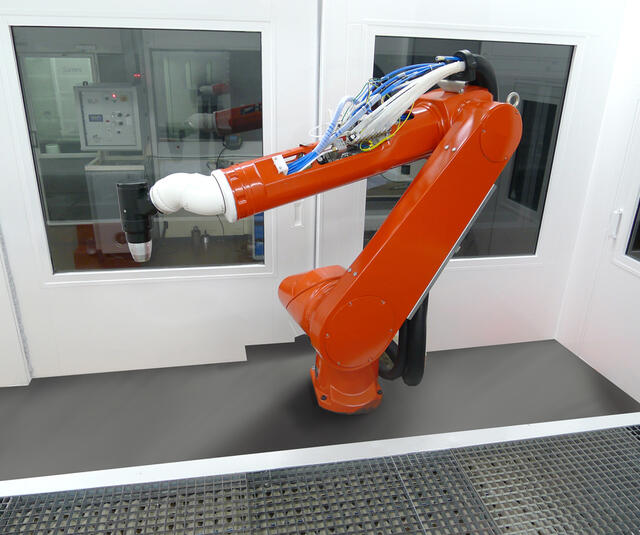

EasyPaint Robot is the best solution

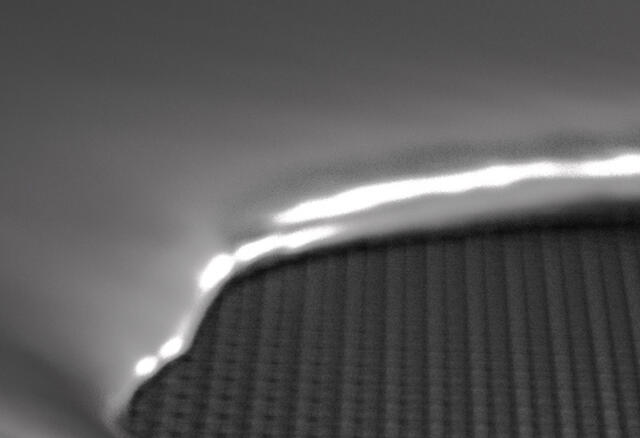

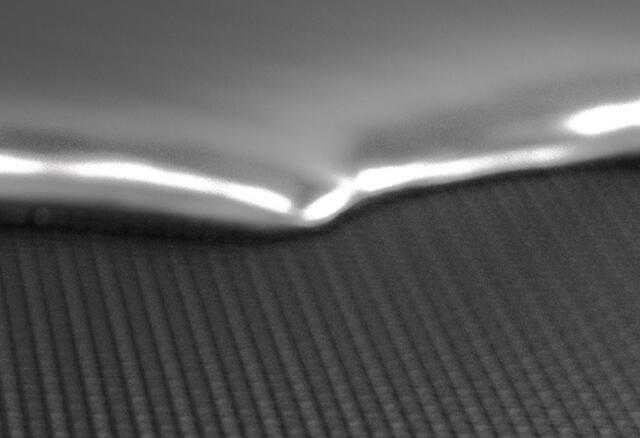

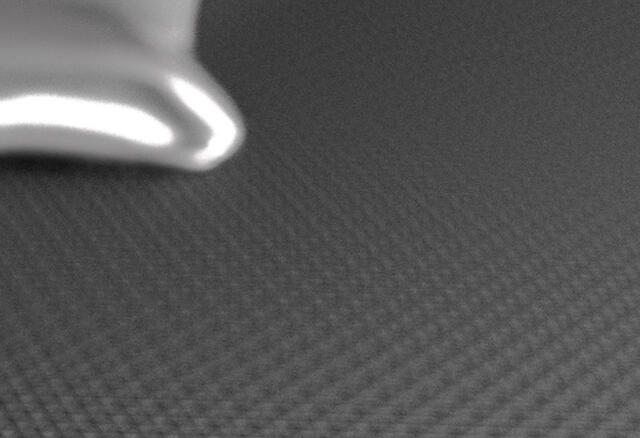

- Because bumpers and other plastic parts painting lines require the highest finishing quality.

- Both investment decision and production life require efficient solution

Complete Solutions to Ensure

- High finishing quality to paint your A Class surface

- Accurate dosing and paint delivering by gear pump

- High transfer efficiency insured by electrostatic bell sprayers

- Standard improve package to minimize study

- Compact color change block for reduced paint losses

- Flexible robotic process

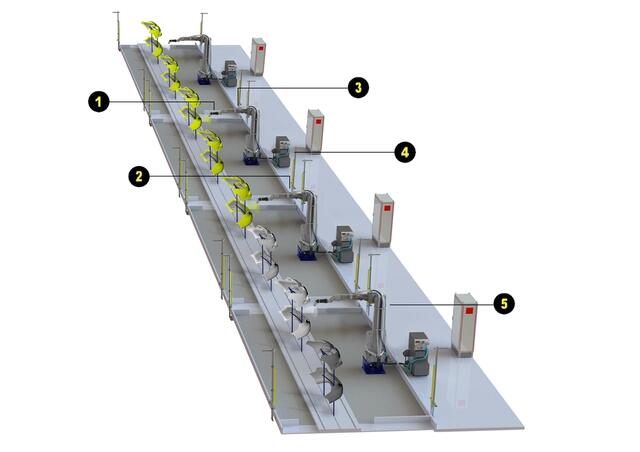

Concept Layout

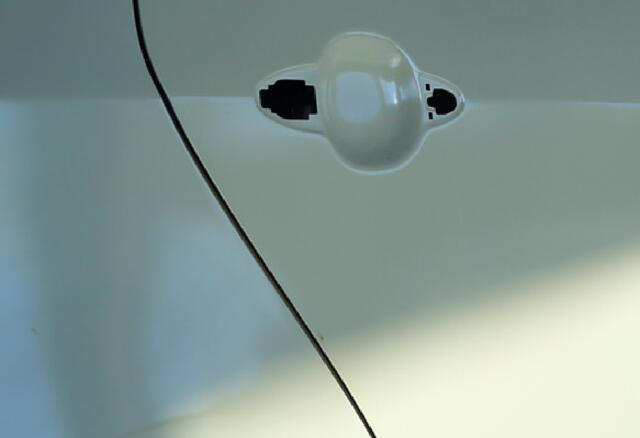

High speed bell atomizer for solventborne material for external bumper

Dedicated bell sprayer for 2 components ClearCoat or primer

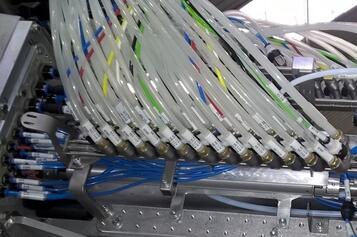

Color change management, light and compact design assembled in the process arm

Fast Cleaning Gearpump for precise paint flow control and bi-pass when flushing

Process control, robot station management including Profinet a& Ethernet connection (other in option).

This high level supervision gives all tools for the operator to monitor production, to plan maintenance actions, to analyse & to improve process management.

FANUC P250 and YASKAWA MPX3500 are standard painting robots available today.

Both ensure high performing painting process with up to 2 integrated drives for paint gear pumps (2K paint), and a large working range.

Mounted options : Floor, wall or top.