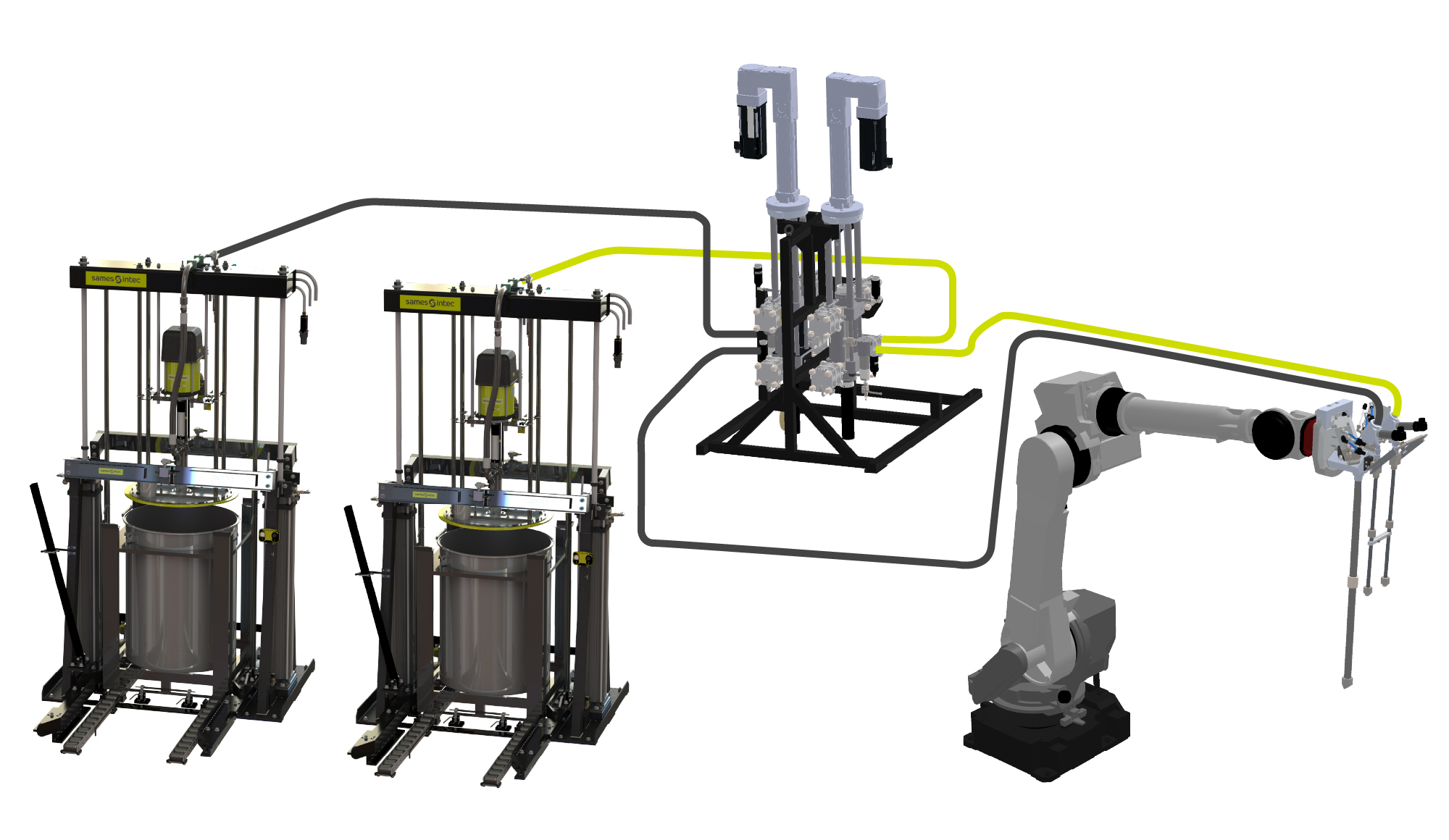

2K large dispense solution

Best in class precision and accurate dispense for 2K high viscosity endless applications

For optimal thermal management, a solution involves the application of 2K (two-component) materials such as epoxy, polyurethane (PU), or silicones as gap fillers or fire protection materials. From the dual-ram unit, each material is pushed to an endless electrical dosing unit to the mixing head. To avoid any risk of clogging, the high flow head is able to flush the mixed volume in few seconds.

Highest flow rate for 2K high viscosity materials = less robots & shortest cycle time

Flushable 2K head to avoid clogging

Up to 300 bar / 4300 psi application pressure for very high viscous materials

Fully heated from drum to the head

The Infinitec dosing unit is based on Rexson 4 balls piston pump. The balls have been replaced by active valves with large diameter, using carbide for seats and needles. Able to push at 300 bar (4350 psi), the output capacity is the highest of the market.