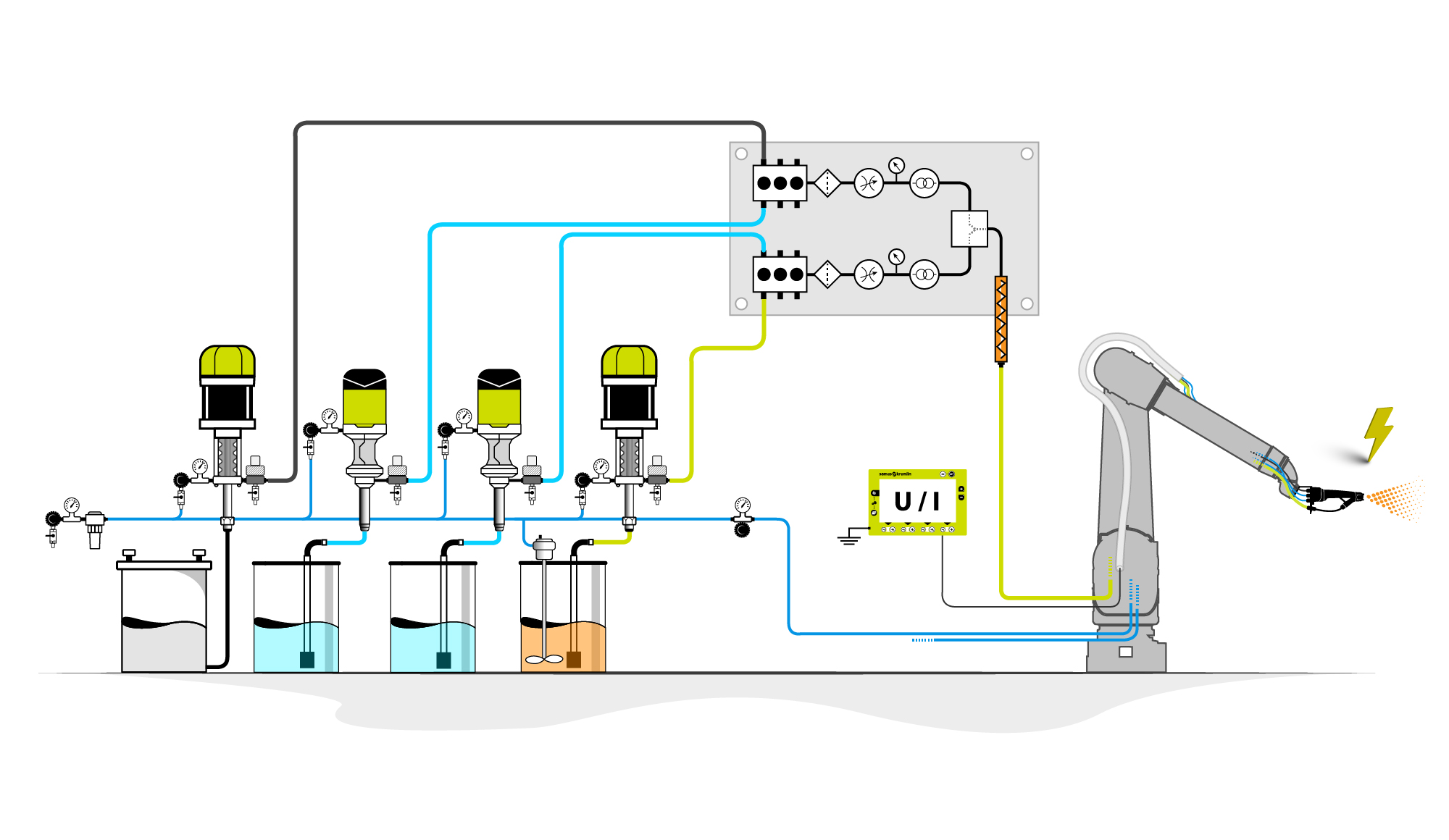

Spray 2K SB (solventborne) paint with automatic electrostatic Airmix® gun

Automate, save up to 35% of paint, 30% of cycle time and obtain high finishing quality with Airmix® electrostatic Nanogun Automatic gun combined with automatic 2K paint mixing technology.

Efficiency: Quantitative savings in paint and application time compared to non-electrostatic Airmix systems.

Simplify the application process: Achieve uniform coating thickness and excellent coverage—even in hidden areas thanks to Sames' powerful electrostatic technology.

Productivity: Automate your coating process and boost production capacity by more than 30%.