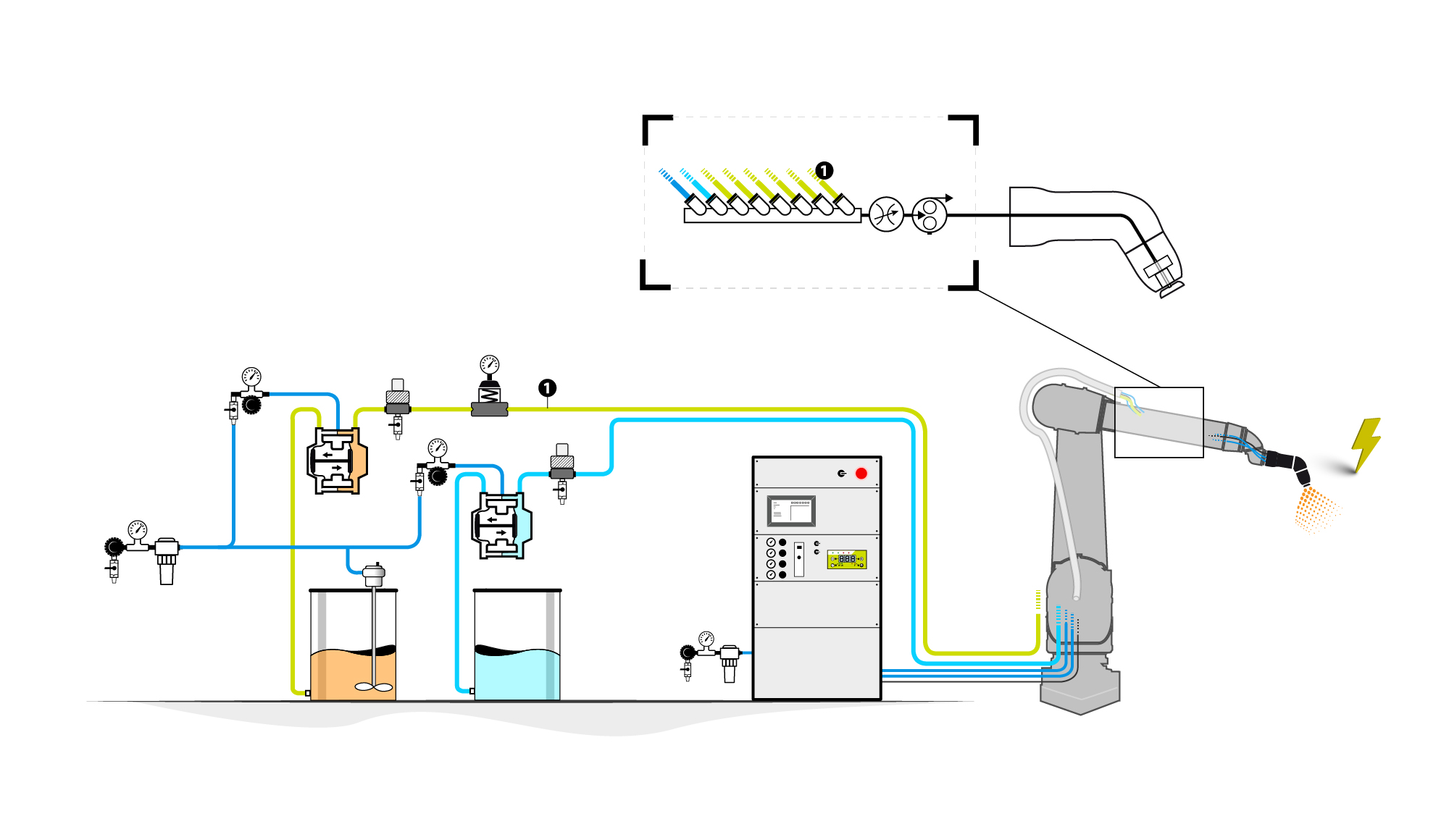

Robotic application solution with a dedicated Viscobell® for solvent-based and water-based paints

High speed Viscobell®: Up to 1 liter/min at high conveyor speed, with a minimum transfer efficiency of 77%. Cleaning cycle: 5 seconds. Color change: Less than 20 seconds. Viscosity: Up to 5000 cps.

Performance: High finishing quality for painting Class A surfaces, and precise dosing and paint delivery.

Productivity: High transfer efficiency ensured by electrostatic bell sprayers.

Sustainability: Standard improvement package to minimize studies, compact color change block to reduce paint losses, flexible robotic process.

Consistency: No risk of paint clogging, and very fast cleaning time for long application periods.

Robotization brings:

- Repeatability and homogeneity: Each part receives the same quality of finish, without human variability

- Reduced scrap: Less overcharging, less rework

- Flexibility: Programming possible for several ranges (doors, windows, jambs, openings)

- Safety & ergonomics: Reduction of risks related to manual workstations (VOCs, fatigue, MSDs)

The rotating bell Viscobell® is designed for hydro and high viscosity paints:

- High transfer: Up to 90% → less paint loss

- Better coverage of complex profiles (mullions, grooves, rebates)

- Thin, even application: Even coat, premium quality

- Reduced paint consumption: Direct savings (up to 30% off)

Typical ROI in 12 to 24 months thanks to:

- Savings in paint and solvents

- Reduction of rework time

- Fewer scrap parts

- Improved productivity and machine utilization rate

Yes, the Viscobell® rotary bell is designed for:

- Water-based paints → better atomization, regular deposit

- High viscosity paints → stability and controlled flow

- New technologies (UV, high-demand varnish) → high-end finish without orange peel skin

Robotization is adapted by programming:

- Program library according to product dimensions and types

- Recognition via conveyor + vision possible

- Reduced changeover time → increased responsiveness

The rotary bell and the robot are designed for intensive use:

- Simple preventive maintenance (cleaning, turbine change)

- Optimized component life

- Technical support & training available for teams

Yes, it allows:

- Reduction of VOCs (less solvents needed)

- Less paint waste (high transfer efficiency)

- Energy optimization (fewer rework, fewer cycles)

Investing in this technology means:

- Increase throughput with consistent quality

- Reduce costs per part (labor + material)

- Strengthen competitiveness against competitors who are already automating

- Enhance the industrial image with customers (innovation, sustainability)