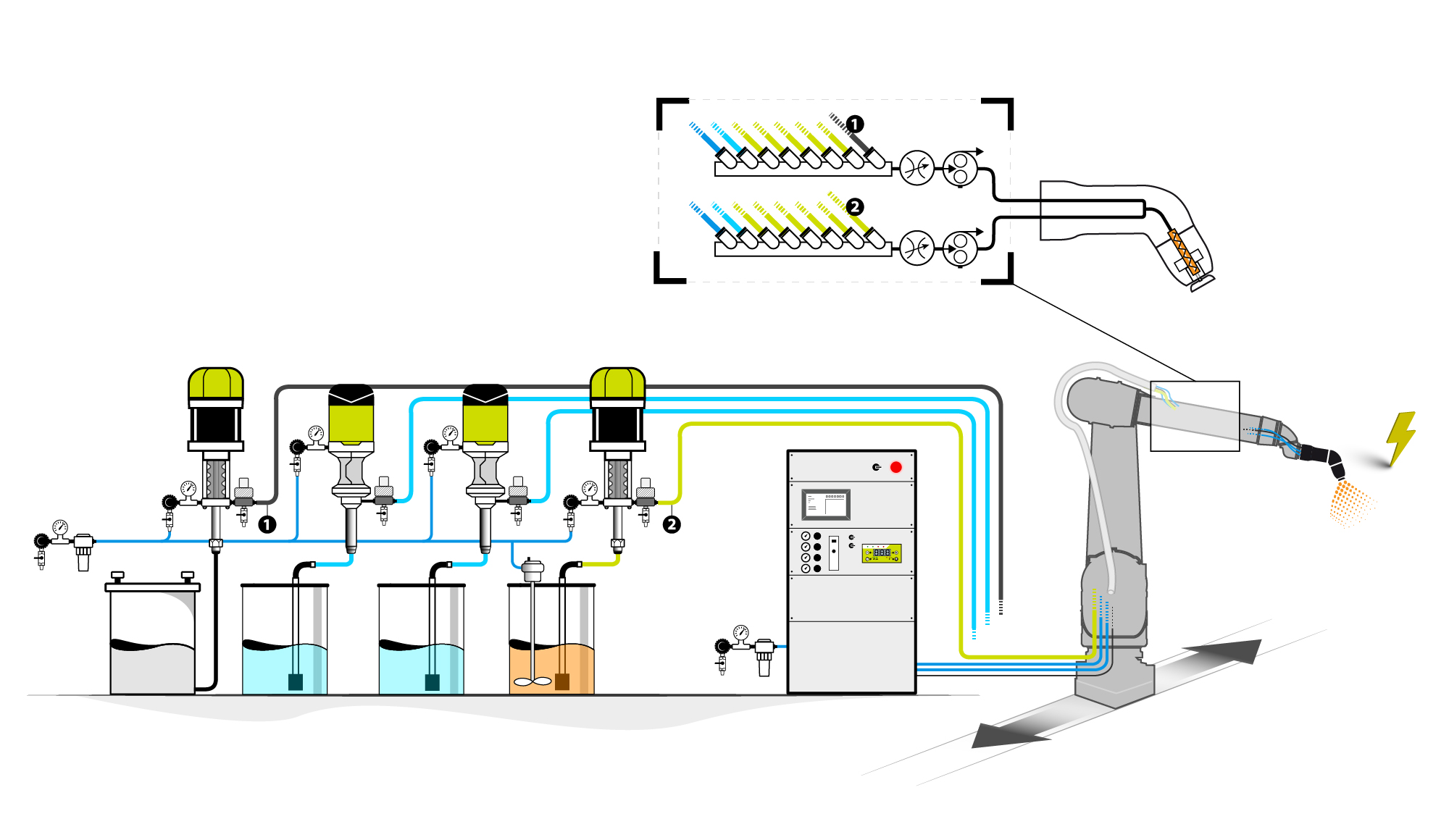

Spray 2K SB (solventborne) primer & topcoat with robotic electrostatic bell

Automate, save up to 50% of paint, 30% of cycle time and obtain better finishing quality with Sames Nanocoat robotic electrostatic rotary bell spraying combined with a process arm 2K antenna embedded onto the robot.

The robot operates in sync with up to two external axes, creating a 8-axis robotic system capable of reaching nearly all rail car surfaces. A final manual touch-up is performed if necessary.

Productivity: Automate your coating process and achieve over a 30% increase in production capacity.

Efficiency: Achieve up to 50% savings in paint compared to non-electrostatic conventional coating technologies.

Coating Quality: Achieve uniform coating thickness and superior coverage, thanks to Sames’ advanced electrostatic technology.

Flexible Solutions: Select from integration packages offered without control, with optional control systems, or as a complete turnkey solution for end customers.

Using the same fluid circuit for both epoxy primer and PU topcoat is strongly discouraged because their hardeners are chemically incompatible, which can cause serious quality issues. However, alternative solutions are available depending on application constraints.