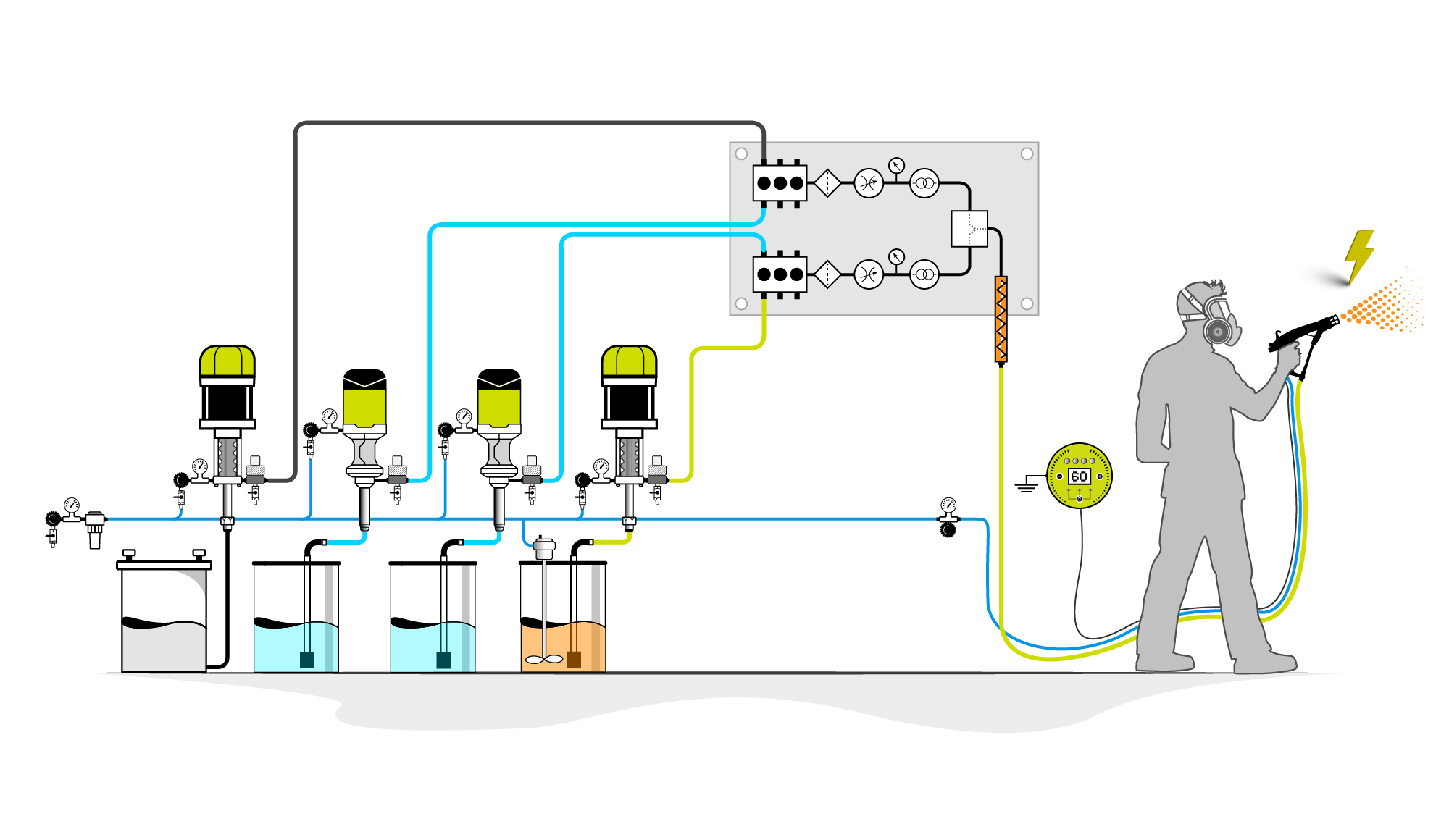

Spray 2K SB (solventborne) paint with electrostatic Airmix® manual gun

Save up to 35% of paint, 30% of cycle time and obtain better finishing quality with Electrostatic Airmix® spraying combined with 2K automatic mixing technology.

Efficient Mixing & Superior Coating Performance

Paint and hardener are pumped and freshly mixed during spraying for optimal quality. Electrostatic charging ensures maximum coating efficiency.

The Cyclomix® Evo automates critical tasks such as pot-life monitoring, color changes, purging, and cleaning—saving time and reducing waste.

Colors are delivered to the color-change valve block by piston pumps that draw paint directly from the original drums. Drums can be equipped with agitators to prevent sedimentation. The hardener is pumped from a sealed tank using the unique Flowmax® pump, fully sealed to protect against humidity.

Our 2K mixing systems (Cyclomix® Evo or PU3000) proportion and mix only during spraying, guaranteeing fresh, homogeneous paint for superior finish. During application, the spray gun electrostatically charges paint droplets, attracting them to the surface for optimal coverage and efficiency.

With Cyclomix® Evo, you benefit from fully automated pot-life control, color changes, purging, and cleaning—delivering precision and productivity every time.

Efficiency: Save paint and reduce application time compared to non-electrostatic methods.

Better Finish Quality: Always spray a fresh paint mix combined with superior atomization using our advanced electrostatic system.

Minimize paint and solvent waste: Mix only what you spray. Up to 50% waste reduction during paint preparation and color changes.

No more rework: Eliminate mixing errors with precise automatic proportioning and mixing operations with 2K mixing machine.