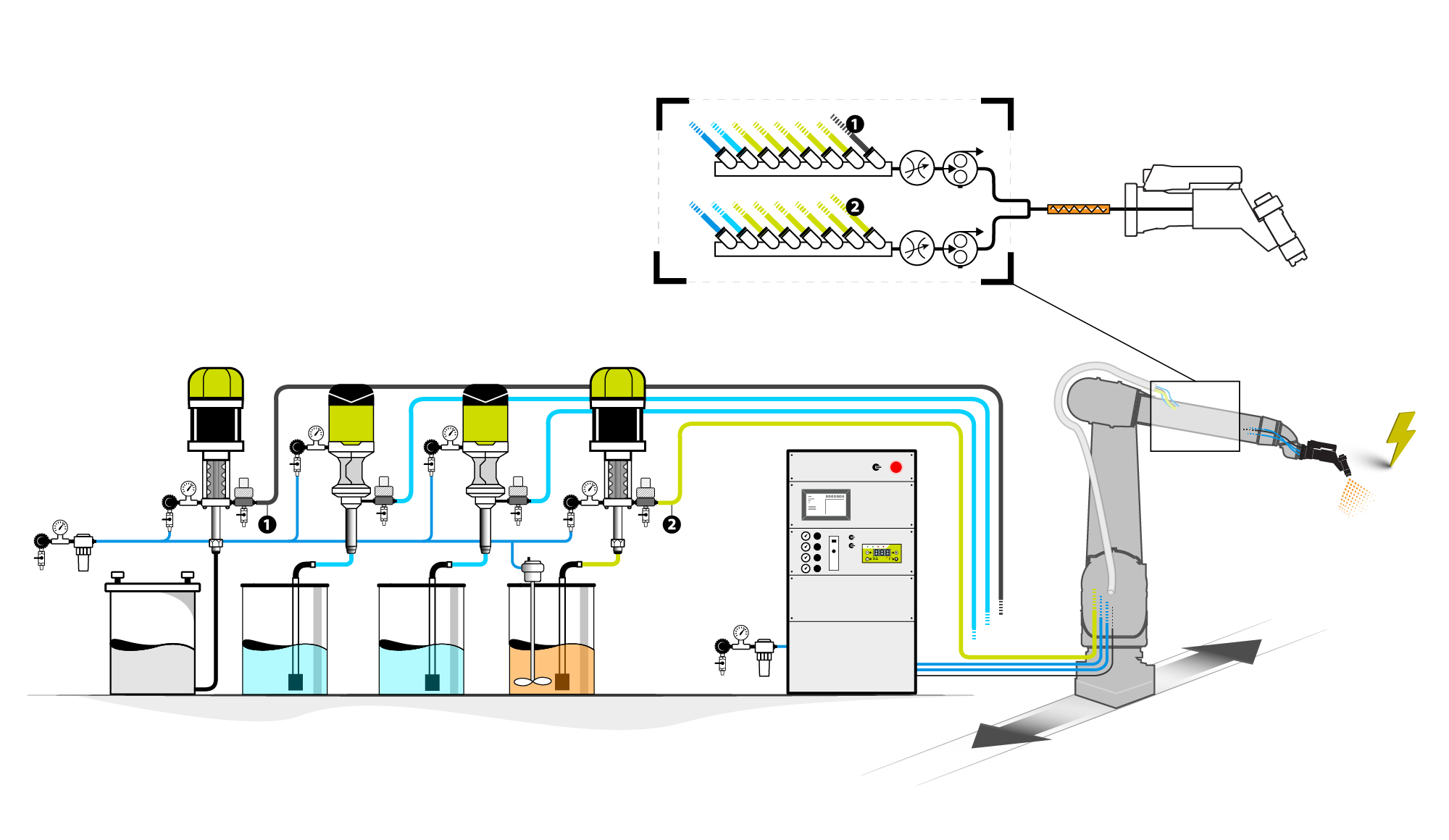

Spray 2K-SB paint with robotic electrostatic twin guns

Automate, save up to 35% of paint, 60% of cycle time, and obtain high finishing quality with Sames Nanocoat electrostatic TRP502 robotic gun spraying combined with a process arm 2K antenna embedded onto the robot.

Base and hardener are pumped at low pressure until the process arm onto the robot.

During the execution of the coating trajectories, both components are dosed with volumetric gear-pumps and mixed just before spraying at high flow rate with TRP502 twin guns.

The robot itself is synchronized with 3 external axes, giving up to 9-axes robotic solution able to reach almost all areas of the truck bed. A final manual touch-up & curing stage is performed after.

Productivity: Automate your coating process and anticipate an increase in production capacity of over 60%.

Efficiency: Achieve up to 35% savings in paint compared conventional non-electrostatic coating technologies.

Coating Quality: Achieve consistent coating thickness and superior coverage, thanks to Sames’ advanced electrostatic technology.

Flexible Solutions: Select from integration packages offered without control, with optional control systems, or as a complete turnkey solution for end customers

Electrostatic spraying greatly reduces paint consumption by improving transfer efficiency—less overspray means lower paint use, reduced maintenance, and consistent, high-quality finishes.

Fast, efficient color-change systems with Upside valves and peripherics help minimize waste and downtime, especially in operations with frequent color switches.

For specialized or small-batch production, Sames offers high-performance solutions like the Cyclomix® Evo 2K dosing machine for precise mixing with minimal waste, and manual spray guns such as the Nanogun (electrostatic Airmix® or airspray), Xcite® (Airmix®), and Fpro (airspray)—all designed for top-quality finishes and maximum paint savings.

Improving transfer efficiency remains the most effective way to cut paint use while maintaining productivity and quality.