Resin infusion process to manufacture rotor blades

In windmill blade production, resin infusion is a key process for creating large, strong, and lightweight composite structures. The dry fiber layers are first laid into the blade mold, then sealed with a vacuum film. Once the vacuum is applied, the resin is injected into the mold, flowing through the fiber layers and fully infusing them before curing.

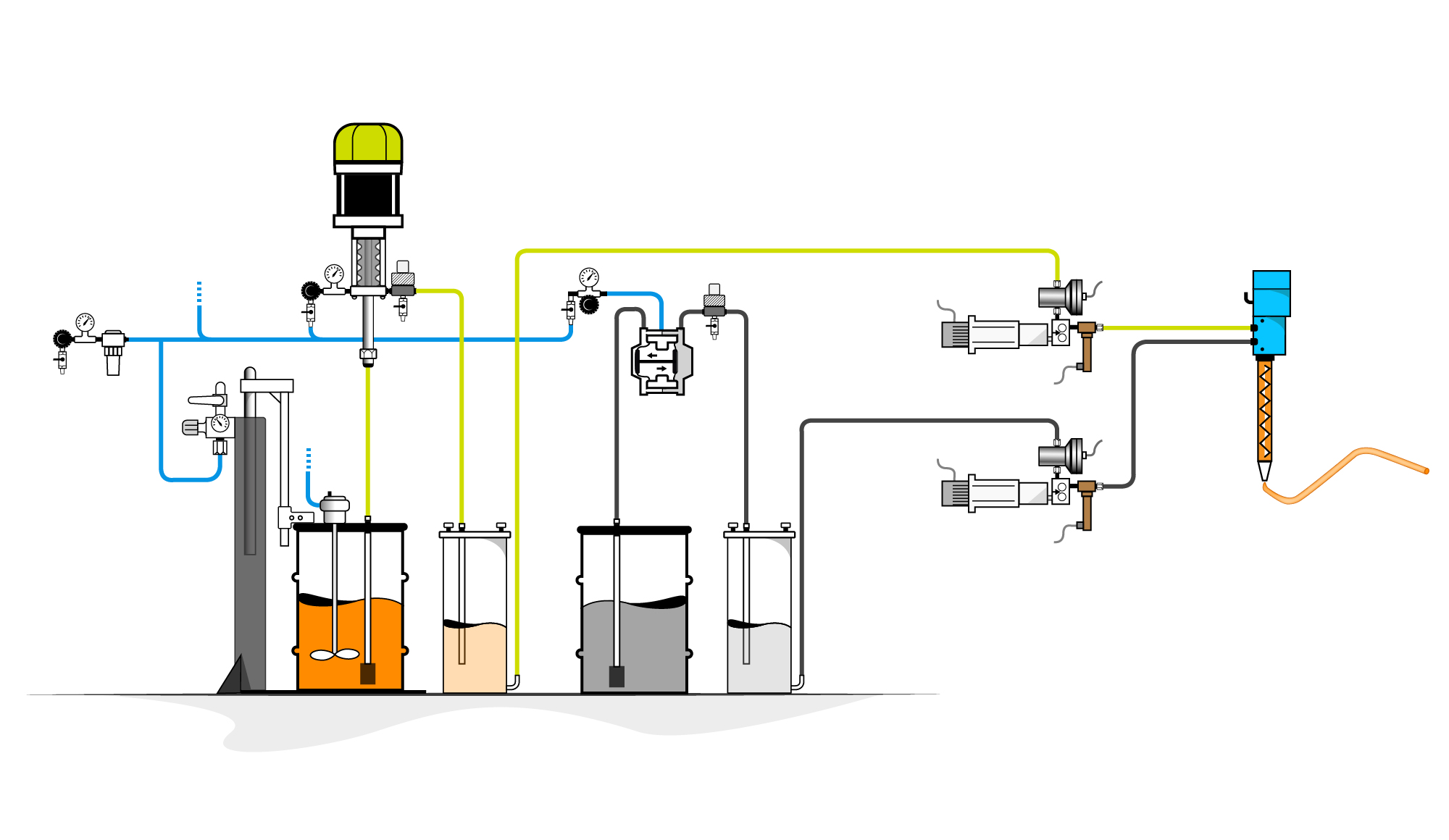

To meet the high demands of this process, Sames offers the E60 mixing and dispensing solution, specifically designed for high viscosity 2K or 3K resins. With a flow rate of up to 25 L/min, the E60 ensures fast and controlled resin delivery, even for large mold volumes.

Sames E60 solution can be configured for 2K or 3K resin systems. Thanks to its reliability and process control, the E60 solution is widely used in the composite manufacturing industry, including for wind turbine blade production. It is also known to be a cost-effective solution.

For further details or a tailored solution to your process, feel free to contact our team.

Precise metering via high-performance gear proportioners

Disposable static mixer for clean and efficient 2K/3K mixing

Pouring application method adapted for resin infusion process

Optional gear flow meter for advanced process monitoring

Stationary design, ideal for integration in production lines

Resin infusion of large structures like wind turbine blades requires precise control over flow rate, resin distribution, and curing time to ensure full impregnation of the fiber layers without air pockets or dry zones. The large size of molds and high viscosity of structural resins make flow control and consistent mixing critical to avoid defects.

Inaccurate mixing of multi-component resins can lead to weak mechanical properties, incomplete curing, or part rejection. Equipment like the Sames E60 ensures consistent ratio control, thorough mixing via disposable static mixers, and eliminates manual error—critical for quality and structural integrity in such demanding applications.

Yes, the E60 is designed to handle both 2K and 3K resin systems, including high viscosity epoxies and polyurethanes commonly used in rotor blade manufacturing. Its modular configuration and optional flow meter make it highly adaptable to different formulations and process parameters.