WATERBASED BELL SOLUTION

Complete Solutions to ensure

- high finishing bell quality

- Uniformity of the film built

- high transfer efficiency with a simple design for waterborne electrostatic process

- high flow rate, for a maximized painted surface per hour

- Long production shift with limited cleaning periods due to our patented efficient charge ring

- high MTBF

- Long life of the robust components

- Low running costs

- 7 years warranty of the turbine

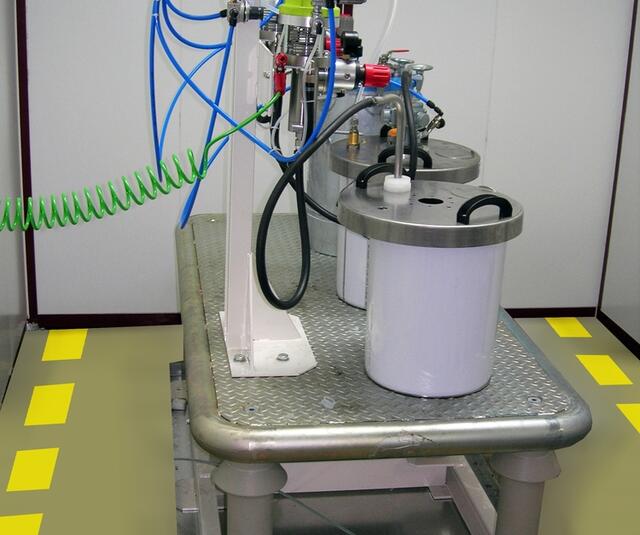

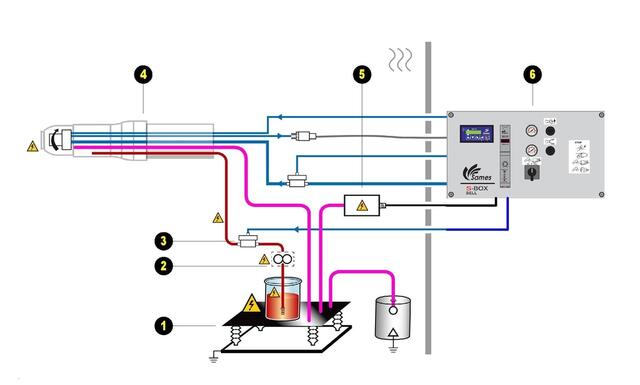

Concept Layout

Insure system insulation when waterbased material is sprayed out

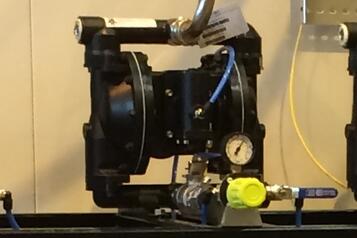

Transfer the material from the drum to the application, could be diaphgram pump (on picure), pressure pot or piston pump.

Controlled by S-Box Bell

High speed rotating bell atomizer

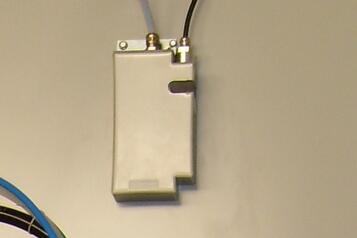

High Voltage Unit

Control unit for shaping air, material flow, flushing process, high voltage control...etc.

Modular conception

This solution is modular and fits all your needs to:

- Handle severral colors on bigger insulating table

- Use small drum size on Isobubble

- Use bigger drum size

- Add motion such as mounting the bell on a reciprocator

- Use more atomizer

- Etc...